Hyundai Accent (HC): Engine Mechanical System / Engine And Transaxle Assembly

Contents:

Engine Cover

1.Remove the engine cover (A).

2.Installation is reverse order of removal

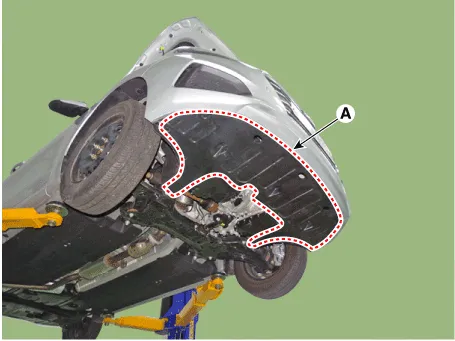

Engine Room Under Cover

1.Remove the engine room under cover (A).

Tightening torque :7.8 - 11.8 N.m (0.8 - 1.2 kgf.m, 5.8 - 8.7 lb-ft)

2.Installation is reverse order of removal.

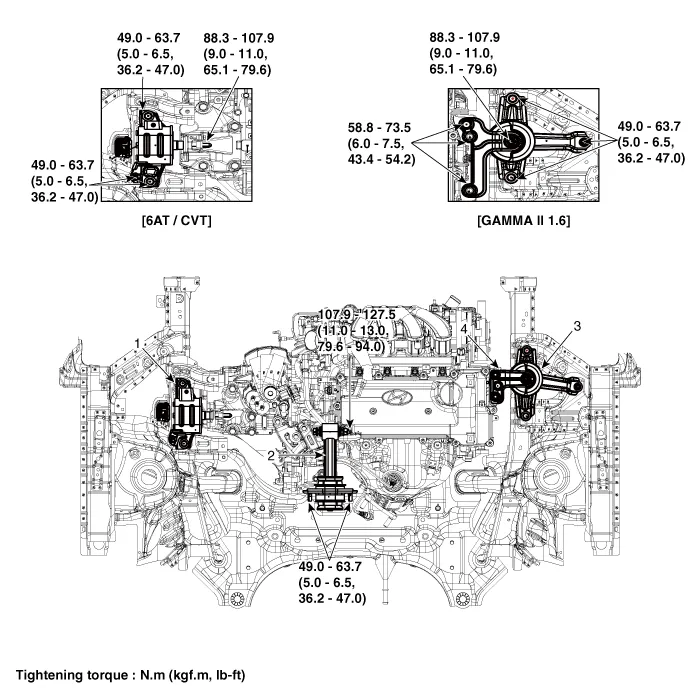

Engine Mounting

1. Transaxle mounting bracket

2. Roll road bracket

3. Engine mounting bracket

4. Engine mounting support bracket

1.Remove the engine room under cover.(Refer to Engine and Transaxle Assembly - "Engine Room Under Cover")

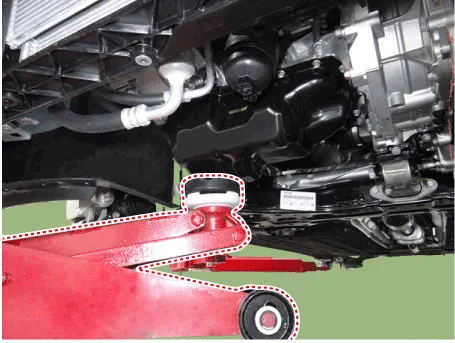

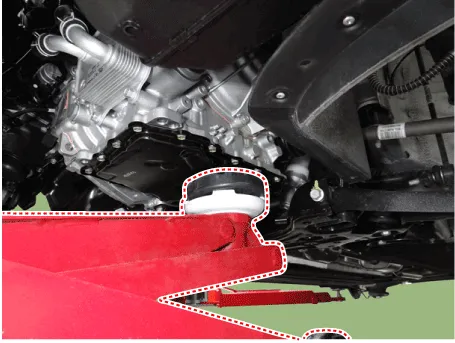

2.Install the jack to the edge of oil pan

• Insert the rubber block between jack and oil pan.

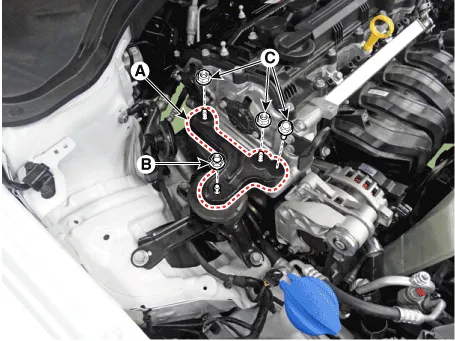

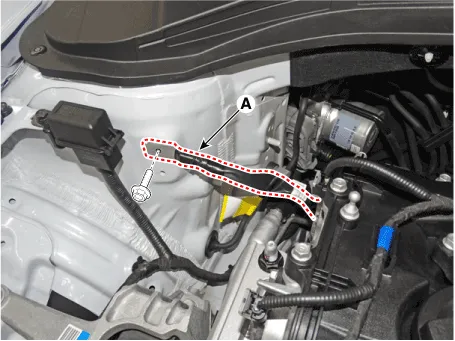

3.Remove the engine mounting support bracket (A).

Tightening torque Nut (B) : 88.3 - 107.9 N.m (9.0 - 11.0 kgf.m, 65.1 - 79.6 lb-ft)Bolt, Nuts (C) : 58.8 - 73.6 N.m (6.0 - 7.5 kgf.m, 43.4 - 54.2 lb-ft)

4.Remove the engine mounting bracket (A).

Tightening torque :49.0 - 63.7 N.m (5.0 - 6.5 kgf.m, 36.2 - 47.0 lb-ft)

5.Install in the reverse order of removal.

1.Disconnect the battery negative terminal.

2.Remove the engine room under cover.(Refer to Engine and Transaxle Assembly - "Engine Room Under Cover")

3.Remove the air duct and air cleaner assembly.(Refer to Intake and Exhaust System - "Air Cleaner")

4.Remove the battery.(Refer to Engine Electrical System - "Battery")

5.Remove the engine control module (ECM).(Refer to Engine Control/Fuel System - "Engine Control Module (ECM)")

6.Remove the battery tray.(Refer to Engine Electrical System - "Battery")

7.Install the jack under the transaxle to support it.

• Insert the rubber block between jack and transaxle.

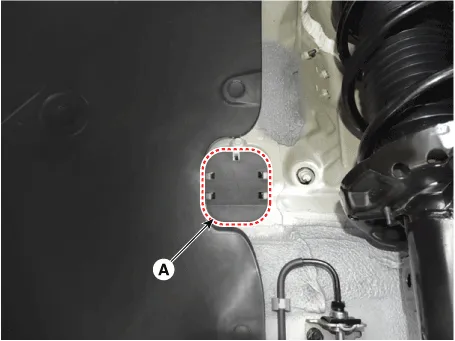

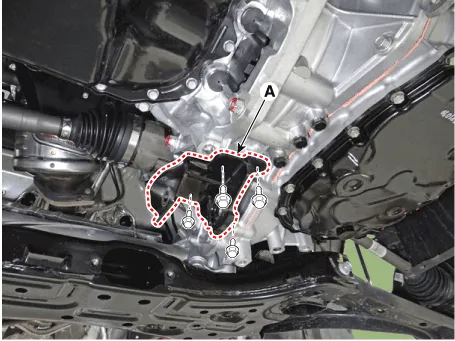

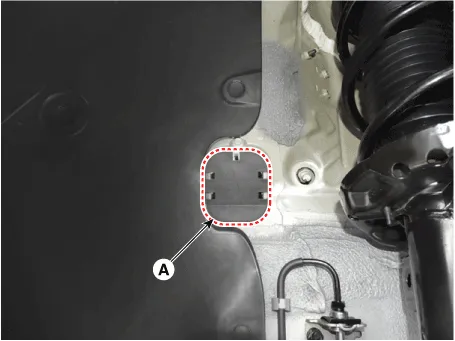

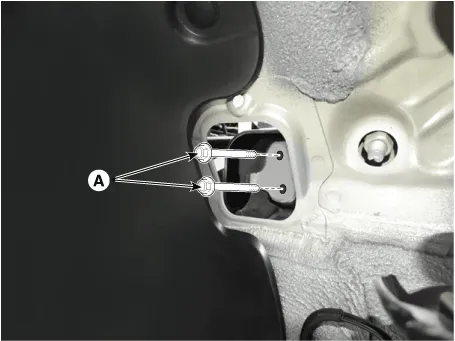

8.Remove the service cover (A).

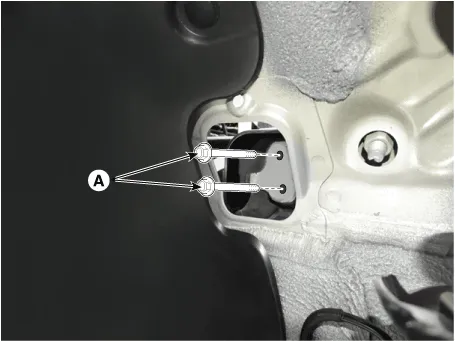

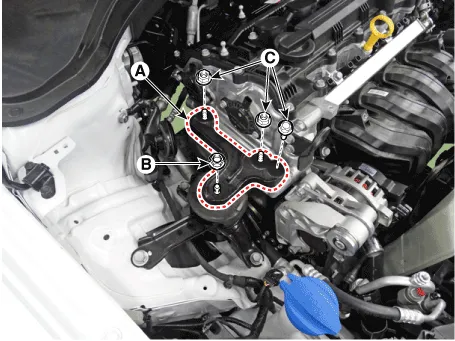

9.Remove the transaxle support bracket mounting bolts (A).

Tightening torque :88.3 - 107.9 N.m (9.0 - 11.0 kgf.m, 65.1 - 79.6 lb-ft)

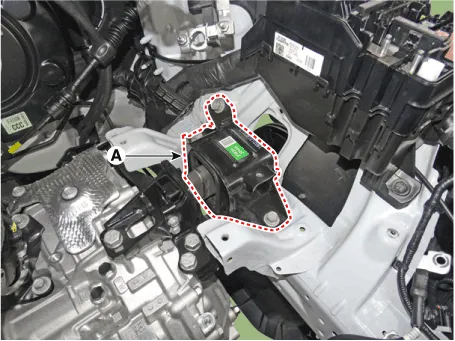

10.Remove the transaxle mounting bracket (A).

Tightening torque : 49.0 - 63.7 N.m (5.0 - 6.5 kgf.m, 36.2 - 47.0 lb-ft)

11.Install in the reverse order of removal.

1.Remove the engine room under cover.(Refer to Engine and Transaxle Assembly - "Engine Room Under Cover")

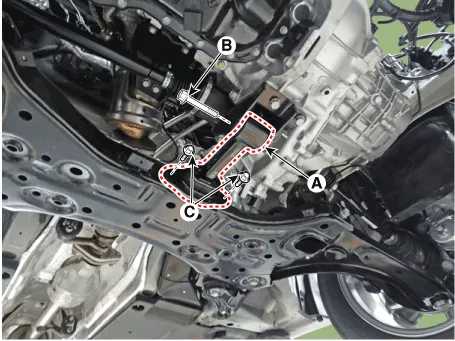

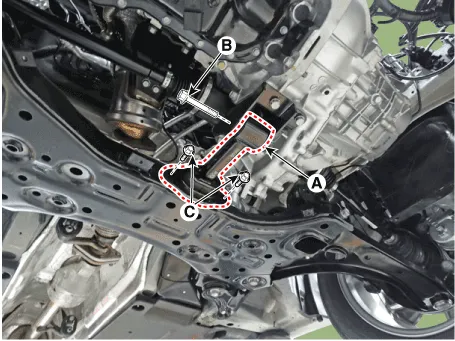

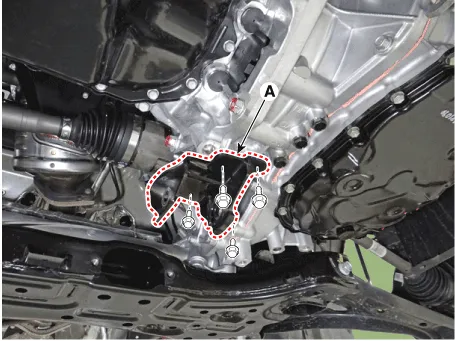

2.Remove the roll rod bracket (A).

Tightening torqueBolt (B) : 107.9 - 127.5 N.m (11.0 - 13.0 kgf.m, 79.6 - 94.0 lb-ft)Bolts (C) : 49.0 - 63.7 N.m (5.0 - 6.5 kgf.m, 36.2 - 47.0 lb-ft)

3.Remove the roll rod suppot bracket (A).

Tightening torque :49.0 - 68.6 N.m (5.0 - 7.0 kgf.m, 36.2 - 50.6 lb-ft)

4.Install in the reverse order of removal.

Engine And Transaxle Assembly

• Use fender covers to avoid damaging painted surfaces.

• To avoid damage, unplug the wiring connectors carefully while holding the connector portion.

• Mark all wiring connector and hoses to avoid misconnection.

1.Disconnect the battery negative terminal.

2.Remove the engine cover(Refer to Engine and Transaxle Assembly - "Engine Cover")

3.Remove the engine room under cover.(Refer to Engine and Transaxle Assembly - "Engine Room Under Cover")

4.Drain the coolant.(Refer to Cooling System - "Coolant")

5.Recover the refrigerant and then remove the high pressure pipe and low pressure pipe.(Refer to Heating, Ventilation Air conditioning - "Compressor")

6.Remove the air duct and air cleaner assembly.(Refer to Intake and Exhaust System - "Air Cleaner")

7.Remove the battery.(Refer to Engine Electrical System - "Battery")

8.Remove the engine control module (ECM).(Refer to Engine Control/Fuel System - "Engine Control Module (ECM)")

9.Remove the battery tray.(Refer to Engine Electrical System - "Battery")

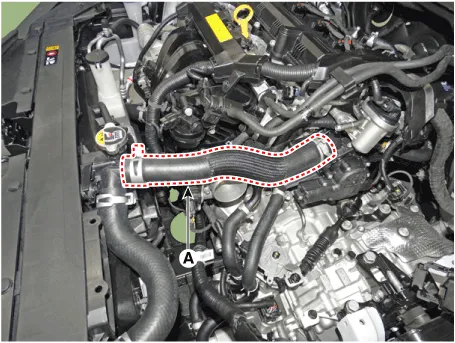

10.Disconnect the radiator upper hose (A).

11.Disconnect the radiator lower hose (A).

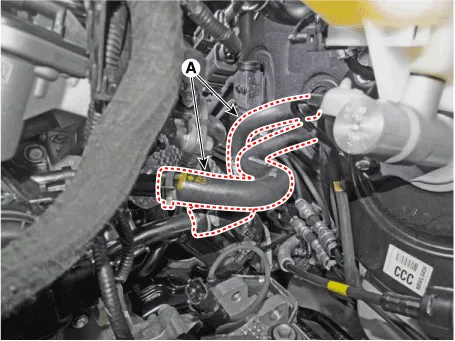

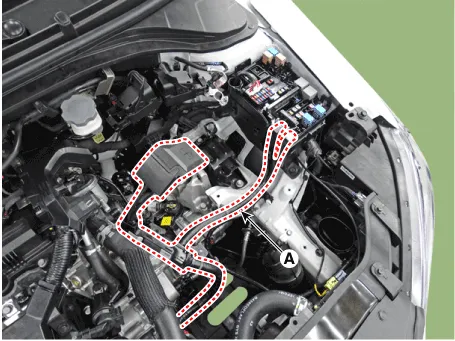

12.Disconnect the brake booster vacuum hose (A).

13.Disconnect the heater hoses (A).

14.Remove the transaxle wire harness connectors and control cable from the transaxle.(Refer to Intelligent Variable Transmission (IVT) System - "Intelligent Variable Transmission (IVT)")(Refer to Manual Transaxle System - "Manual Transaxle")

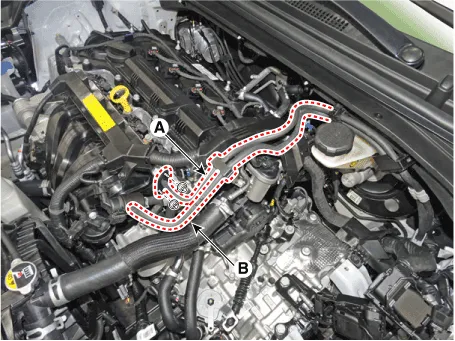

15.Disconnect the fuel hose (A) and purge control solenoid valve (PCSV) hose (B).

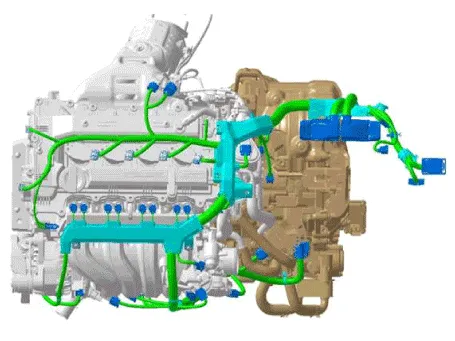

16.Disconnect the wiring connectors and harness clamps and remove the connector brackets around the engine and transaxle assembly.

17.Disconnect the battery positive wirings (A)

18.Remove the front muffler.(Refer to Intake and Exhaust System - "Muffler")

19.Remove the roll rod bracket (A).

Tightening torque Bolt (B) : 107.9 - 127.5 N.m (11.0 - 13.0 kgf.m, 79.6 - 94.0 lb-ft)Bolts (C) : 49.0 - 63.7 N.m (5.0 - 6.5 kgf.m, 36.2 - 47.0 lb-ft)

20.Remove the roll rod support bracket (A).

Tightening torque : 49.0 - 68.6 N.m (5.0 - 7.0 kgf.m, 36.2 - 50.6 lb-ft)

21.Remove the steering U-joint mounting bolt.(Refer to Steering System - "Steering Gear Box")

22.Remove the sub frame.(Refer to Suspension System - "Sub Frame")

23.Support the Engine and Transaxle Assembly with a floor jack.

24.Remove the engine mounting support bracket (A).

Tightening torque :Bolt (B) : 88.3 - 107.9 N.m (9.0 - 11.0 kgf.m, 65.1 - 79.6 lb-ft)Bolt, Nuts (C) : 58.8 - 73.6 N.m (6.0 - 7.5 kgf.m, 43.4 - 54.2 lb-ft)

25.Disconnect the engine ground (A).

Tightening torque : 10.8 - 13.7 N.m (1.1 - 1.4 kgf.m, 8.0 - 10.1 lb-ft)

26.Remove the service cover (A).

27.Remove the transaxle support bracket mounting bolts (A).

Tightening torque : 88.3 - 107.9 N.m (9.0 - 11.0 kgf.m, 65.1 - 79.6 lb-ft)

28.Disconnect the transaxle ground cable (A).

Tightening torque : 10.8 - 13.7 N.m (1.1 - 1.4 kgf.m, 8.0 - 10.1 lb-ft)

29.Remove the engine and transaxle assembly by lifting vehicle.

• Before removing the engine and transaxle assembly, make sure hoses and wire connectors are disconnected.

• When removing the engine and transaxle assembly, be careful not to damage any surrounding parts or body components.

1.Install in the reverse order of removal.

2.Fill with engine coolant. (Refer to Cooling System - "Coolant")

• The coolant must be injected according to the integrated thermal management module (ITM) coolant filling method.

Perform the following• Refill the transaxle with fluid.

• Inspect for fuel leakage.

– After assemble the fuel line, turn on the ignition switch (do not operate the starter) so that the fuel pump runs for approximately two seconds and fuel line pressurizes.

– Repeat this operation two or three times, then check for fuel leakage at any point in the fuel line.

• Clean battery posts and cable terminals with sandpaper assemble them, then apply grease to prevent corrosion.

Other information:

Hyundai Accent (HC) (2017 - 2022) Service Manual: Exterior Lights

Lighting control To operate exterior lighting on the Hyundai Accent, rotate the knob at the end of the control lever to one of the positions listed below. The available positions may differ by type and equipment. â– Type A â– Type B â– Type C Type A (1) OFF position (2) Parking lamp position (3) Headlamp position Type B (1) OFF position (2) AUTO light position (3) Parking lamp position (4) Headlamp position Type C (1) DRL OFF position (2) AUTO position (3) Parking lamp position (4) Headlamp position Daytime running light (DRL) The Daytime Running Lights (DRL) help other road users notice the front of your Hyundai Accent during daytime driving, particularly in low-angle light after dawn and before sunset.Hyundai Accent (HC) (2017 - 2022) Service Manual: Vehicle load limit

Two labels on your driver’s door sill show how much weight your Hyundai Accent was designed to carry: the Tire and Loading Information Label and the Certification Label. These labels help you confirm safe loading limits before you add passengers or cargo. Before loading your Hyundai Accent, familiarize yourself with the following terms for determining your vehicle’s weight ratings, based on the vehicle specifications and the Certification Label: Base Curb Weight This is the weight of the vehicle including a full tank of fuel and all standard equipment.

Contents

Categories

- Manuals Home

- Hyundai Accent Owners Manual

- Hyundai Accent Service Manual

- Questions & Answers

- Video Guides

- Useful Resources

- New on site

- Most important about car

- Privacy Policy

0.0042