Hyundai Accent (HC): General Information

Contents:

- Important Safety Notice

- Identification Numbers

- Warning and Caution Labels

- Lift and Support Points

- General Tightening Torque Table

- Basic Service Symbols

- General Service Information

Important Safety Notice

- Important Safety Notice

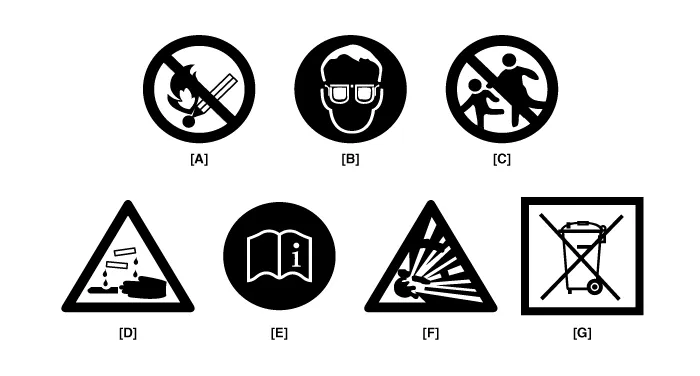

Proper service methods and repair procedures are essential for safe, reliable operation of all motor vehicles as well as personal safety of the operator. The service procedures and descriptions in this shop manual provide general directions for service and repair. There are various procedures, techniques, tools and pars for service as well as the skill of technicians.Therefore, it is impossible for this manual to provide advice or caution for each case. Accordingly, if you use a replacement part, service procedure, or tool which are not recommended by the vehicle manufacturer, make sure that neither the personal safety nor the safe operation of the vehicle is jeopardized.

• Reminds you to be especially careful in those areas where carelessness will cause death or serious injury.

• Reminds you to be especially careful in those areas where carelessness may cause death or serious injury.

• Reminds you to be especially careful in those areas where carelessness may cause personal injury.

• Gives you information that will prevent you from making errors that could damage the vehicle.

• Gives you additional information that will help you complete a particular procedure.

The following list contains some general WARNINGS that you should follow while working on a vehicle.

• Always wear safety glasses for eye protection.

• Use safety stands whenever a procedure requires you to be under the vehicle.

• Make sure that the ignition switch is always in the OFF position, unless otherwise required by the procedure.

• Set the parking brake when working on the vehicle. If you have an automatic transaxle, set the vehicle in the P position.

• Place supporters against the front and rear surfaces of the tires to prepare for the vehicle suddenly moving.

• Operate the engine only in a well-ventilated area to avoid the danger of carbon monoxide poisoning.

• Keep yourself and your clothing away from moving parts when the engine is running, especially the drive belts.

• To prevent serious burns, avoid contact with hot metal parts such as the radiator, exhaust manifold, tail pipe, catalytic converter and muffler.

• Do not smoke while working on a vehicle.

• To avoid injury, always remove rings, watches, loose hanging jewelry, and loose clothing before beginning to work on a vehicle.

• When it is necessary to work under the hood, keep hands and other objects clear of the radiator fan blades! Your vehicle may be equipped with a cooling fan that may turn on, even though the ignition switch is in the OFF position. For this reason care should be taken to ensure that the radiator fan electric motor is completely disconnected when working under the hood and that the engine is not running.

Identification Numbers

- Important Safety Notice

Proper service methods and repair procedures are essential for safe, reliable operation of all motor vehicles as well as personal safety of the operator. The service procedures and descriptions in this shop manual provide general directions for service and repair. There are various procedures, techniques, tools and pars for service as well as the skill of technicians.Therefore, it is impossible for this manual to provide advice or caution for each case. Accordingly, if you use a replacement part, service procedure, or tool which are not recommended by the vehicle manufacturer, make sure that neither the personal safety nor the safe operation of the vehicle is jeopardized.

• Reminds you to be especially careful in those areas where carelessness will cause death or serious injury.

• Reminds you to be especially careful in those areas where carelessness may cause death or serious injury.

• Reminds you to be especially careful in those areas where carelessness may cause personal injury.

• Gives you information that will prevent you from making errors that could damage the vehicle.

• Gives you additional information that will help you complete a particular procedure.

The following list contains some general WARNINGS that you should follow while working on a vehicle.

• Always wear safety glasses for eye protection.

• Use safety stands whenever a procedure requires you to be under the vehicle.

• Make sure that the ignition switch is always in the OFF position, unless otherwise required by the procedure.

• Set the parking brake when working on the vehicle. If you have an automatic transaxle, set the vehicle in the P position.

• Place supporters against the front and rear surfaces of the tires to prepare for the vehicle suddenly moving.

• Operate the engine only in a well-ventilated area to avoid the danger of carbon monoxide poisoning.

• Keep yourself and your clothing away from moving parts when the engine is running, especially the drive belts.

• To prevent serious burns, avoid contact with hot metal parts such as the radiator, exhaust manifold, tail pipe, catalytic converter and muffler.

• Do not smoke while working on a vehicle.

• To avoid injury, always remove rings, watches, loose hanging jewelry, and loose clothing before beginning to work on a vehicle.

• When it is necessary to work under the hood, keep hands and other objects clear of the radiator fan blades! Your vehicle may be equipped with a cooling fan that may turn on, even though the ignition switch is in the OFF position. For this reason care should be taken to ensure that the radiator fan electric motor is completely disconnected when working under the hood and that the engine is not running.

Warning and Caution Labels

- Warning and Caution Labels

1. Radiator cap caution

2. Fan caution

3. Battery caution

Attention

| Srs Vehicle This car is equipped with a supplemental restraint system. To provide continued reliability, certain elements of the supplemental restraint system shall be serviced or replaced by an authorized dealer ten years after vehicle label.For further information. see owner's manual. Side Air Bag This vehicle is equipped with a side airbag system. To provide continued reliability, certain elements of the side airbag system shall be serviced or vehicle manufacturing date shown on the certification label. For further information, refer to the owner’s manual. |

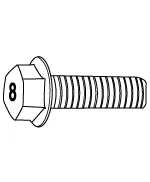

Battery Caution Label Description

Warning / Caution Label (Cont'd)

| A. Keep lighted cigarettes and all other flames or sparks away from the battery. |

| B. Wear safety glasses for eye protection when charging or working near a battery. Always provide ventilation when working in an enclosed space.

|

| C. Keep batteries out of the reach of children because batteries contain highly corrosive SULFURIC ACID. Do not allow battery acid to contact your skin, eyes, clothing or paint finish. |

| D. If any electrolyte gets into your eyes, rinse off your eyes with clean water for at least 15 minutes and get immediate medical attention. If possible, continue to apply water with a sponge or cloth until medical attention is received. If electrolyte gets on your skin, thoroughly wash the contacted area. If you feel a pain or a burning sensation, get medical attention immediately. |

| E. Always read the following instructions carefully before handling a battery. |

| F. Hydrogen, which is a highly combustible gas,is always contained in battery cells and may explode if ignited. |

| G. An improperly disposed battery can be harmful to the environment and human health. Always confirm local regulations for battery disposal. |

Battery Handling and Storage

| Battery |

|

||||||

| Battery installed in vehicle |

|

• After reconnecting or recharging a discharged battery, the ESP OFF indicator may illuminate.

• In this case, turn the handle half way to the left and right whilst the ignition switch is in the ON position.

• Then, restart the engine after the ignition is OFF.

• The ESP OFF indicator may turn OFF.

• If the ESP OFF indicator does not turn OFF, have the system checked by referring to DTC. (Refer to the BR group.)

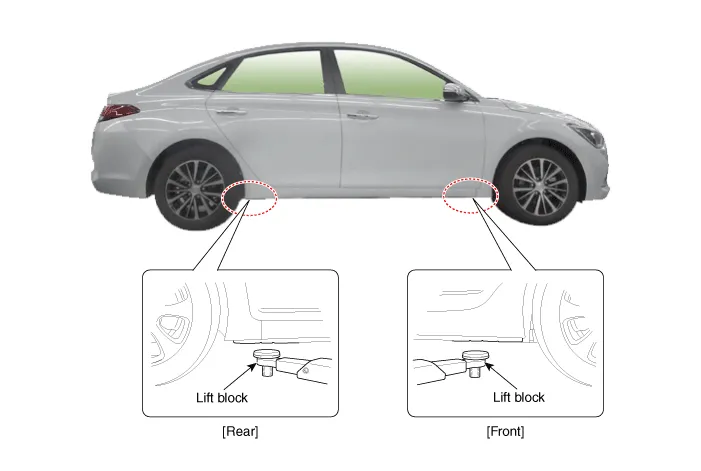

Lift and Support Points

- Lift and Support Points

• When heavy rear components such as suspension, fuel tank, spare tire, tailgate and trunk lid are to be removed, place additional weight in the luggage area before hoisting. When substantial weight is removed from the rear of the vehicle, the center of gravity may change and can cause the vehicle to tip forward on the hoist.

• With each tire/wheel assembly weighing approximately 30lbs (14kg), placing the front wheels in the luggage area can help the weight distribution.

• Use the same support points to support the vehicle on safety stands.

1.Place the lift blocks under the support points as shown in the illustration.

2.Raise the hoist a few inches (centimeters) and rock the vehicle to make sure that the vehicle is firmly supported.

3.Raise the hoist to full height to check whether the vehicle is firmly supported.

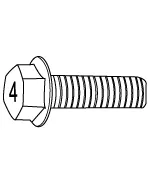

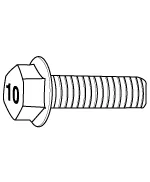

General Tightening Torque Table

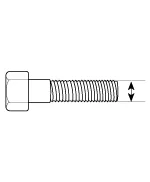

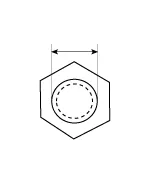

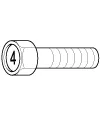

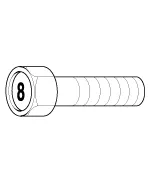

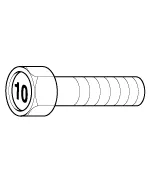

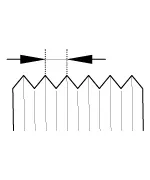

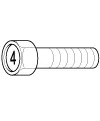

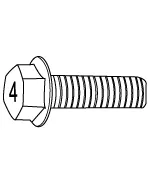

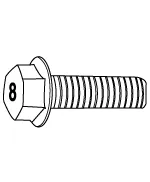

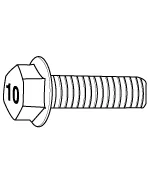

- Tightening Torque Table of Standard Parts

| BOLT (Nominal diameter) | NUT (Nominal diameter) | ||

|

|

|

| BOLT/NUT Normal screw | Torque Nm (kg.m, Ib-ft) | |||

Nominal diameter. (mm) |

Pitch [mm (in.) ] | 4T | 8T | 10T |

|

|

|

|

|

|

| M5 | 0.8 (0.031) | 2.0 - 3.0 (0.2 - 0.3, 1.4 - 2.2) | 4.9 - 6.9 (0.5 - 0.7, 3.6 - 5.1) | 7.8 - 10.8 (0.8 - 1.1, 5.8 - 8.0) |

| M6 | 1 (0.039) | 2.9 - 4.9 (0.3 - 0.5, 2.2 - 3.6) | 8.8 - 12.7 (0.9 - 1.3, 6.5 - 9.4) | 13.7 - 18.6 (1.4 - 1.9, 10.1 - 13.7) |

| M8 | 1.25 (0.049) | 8.8 - 11.8 (0.9 - 1.2, 6.5 - 8.7) | 22.6 - 30.4 (2.3 - 3.1, 16.6 - 22.4) | 33.3 - 44.1 (3.4 - 4.5, 24.6 - 32.5) |

| M10 | 1.5 (0.059) | 16.7 - 22.6 (1.7 - 2.3, 12.3 - 16.6) | 45.1 - 60.8 (4.6 - 6.2, 33.3 - 44.8) | 65.7 - 88.3 (6.7 - 9.0, 48.5 - 65.1) |

| M12 | 1.75 (0.068) | 29.4 - 39.2 (3.0 - 4.0, 21.7 - 28.9) | 78.5 - 105.9 (8.0 - 10.8, 57.9 - 78.1) | 114.7 - 154.9 (11.7 - 15.8, 84.6 - 114.3) |

| M14 | 2 (0.078) | 47.1 - 63.7 (4.8 - 6.5, 34.7 - 47.0) | 125.5 - 169.7 (12.8 - 17.3, 92.6 - 125.1) | 183.4 - 249.1 (18.7 - 25.4, 135.3 - 183.7) |

| M16 | 2 (0.078) | 73.5 - 100.0 (7.5 - 10.2, 54.2 - 73.8) | 197.1 - 266.7 (20.1 - 27.2, 145.4 - 196.7) | 288.3 - 390.3 (29.4 - 39.8, 212.7 - 287.9) |

| M20 | 2.5 (0.098) | 144.2 - 195.2 (14.7 - 19.9, 106.3 - 143.9) | 396.2 - 535.4 (40.4 - 54.6, 292.2 - 394.9) | 565.8 - 764.9 (57.7 - 78.0, 417.3 - 564.2) |

| M24 | 3 (0.118) | 249.1 - 337.3 (25.4 - 34.4, 183.7 - 248.8) | 687.4 - 929.7 (70.1 - 94.8, 507.0 - 685.7) | 975.8 - 1320.0 (99.5 - 134.6, 719.7 - 973.6) |

| M30 | 3.5 (0.137) | 499.2 - 674.7 (50.9 - 68.8, 368.2 - 497.6) | 1372.9 - 1858.4 (140.0 - 189.5, 1012.6 - 1370.7) | 1956.4 - 2647.8 (199.5 - 270.0, 1443.0 - 1952.9) |

| BOLT/NUT Thin screw | Torque Nm (kg.m, Ib-ft) | |||

| Nominal diameter. (mm) |

Pitch [mm (in.) ] | 4T | 8T | 10T |

|

|

|

|

|

|

| M5 | 0.5 (0.019) | 2.0 - 3.0 (0.2 - 0.3, 1.4 - 2.2) | 5.9 - 8.8 (0.6 - 0.9, 4.3 - 6.5) | 8.8 - 12.7 (0.9 - 1.3, 6.5 - 9.4) |

| M6 | 0.75 (0.029) | 3.9 - 4.9 (0.4 - 0.5, 2.9 - 3.6) | 9.8 - 13.7 (1.0 - 1.4, 7.2 - 10.1) | 14.7 - 20.6 (1.5 - 2.1, 10.8 - 15.2) |

| M8 | 1 (0.039) | 8.8 - 11.8 (0.9 - 1.2, 6.5 - 8.7) | 24.5 - 32.4 (2.5 - 3.3, 18.1 - 23.9) | 35.3 - 48.1 (3.6 - 4.9, 26.0 - 35.4) |

| M10 | 1.25 (0.049) | 17.7 - 23.5 (1.8 - 2.4, 13.0 - 17.4) | 47.1 - 63.7 (4.8 - 6.5, 34.7 - 47.0) | 69.6 - 94.1 (7.1 - 9.6, 51.4 - 69.4) |

| M12 | 1.25 (0.049) | 32.4 - 44.1 (3.3 - 4.5, 23.9 - 32.5) | 86.3 - 117.7 (8.8 - 12.0, 63.7 - 86.8) | 127.5 - 172.6 (13.0 - 17.6, 94.0 - 127.3) |

| M14 | 1.5 (0.059) | 51.0 - 69.6 (5.2 - 7.1, 37.6 - 51.4) | 136.3 - 185.3 (13.9 - 18.9, 100.5 - 136.7) | 201.0 - 271.6 (20.5 - 27.7, 148.3 - 200.4) |

| M16 | 1.5 (0.059) | 79.4 - 107.9 (8.1 - 11.0, 58.6 - 79.6) | 211.8 - 286.4 (21.6 - 29.2, 156.2 - 211.2) | 311.8 - 421.7 (31.8 - 43.0, 230.0 - 311.0) |

| M20 | 1.5 (0.059) | 163.8 - 221.6 (16.7 - 22.6, 120.8 - 163.5) | 448.2 - 607.0 (45.7 - 61.9, 330.5 - 447.7) | 639.4 - 864.9 (65.2 - 88.2, 471.6 - 638.0) |

| M24 | 2 (0.078) | 276.5 - 373.6 (28.2 - 38.1, 204.0 - 275.6) | 759.0 - 1026.8 (77.4 - 104.7, 559.8 - 757.3) | 1080.7 - 1462.2 (110.2 - 149.1, 797.1 - 1078.4) |

| M30 | 2 (0.078) | 562.9 - 762.0 (57.4 - 77.7, 415.2 - 562.0) | 1553.4 - 2102.5 (158.4 - 214.4, 1145.7 - 1550.8) | 2210.4 - 2991.0 (225.4 - 305.0, 1630.3 - 2206.1) |

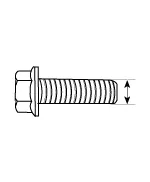

| Flange BOLT (Nominal diameter) | Flange NUT (Nominal diameter) | ||

|

|

|

| Flange BOLT/NUT Normal screw | Torque Nm (kg.m, Ib-ft) | |||

| Nominal diameter. (mm) |

Pitch [ mm (in.) ] | 4T | 8T | 10T |

|

|

|

|

|

|

| M5 | 0.8 (0.031) | 2.0 - 2.9 (0.2 - 0.3, 1.4 - 2.2) | 5.9 - 7.8 (0.6 - 0.8, 4.3 - 5.8) | 8.8 - 11.8 (0.9 - 1.2, 6.5 - 8.7) |

| M6 | 1 (0.039) | 3.9 - 4.9 (0.4 - 0.5, 2.9 - 3.6) | 9.8 - 13.7 (1.0 - 1.4, 7.2 - 10.1) | 14.7 - 19.6 (1.5 - 2.0, 10.8 - 14.5) |

| M8 | 1.25 (0.049) | 8.8 - 11.8 (0.9 - 1.2, 6.5 - 8.7) | 24.5 - 32.4 (2.5 - 3.3, 18.1 - 23.9) | 35.3 - 48.1 (3.6 - 4.9, 26.0 - 35.4) |

| M10 | 1.5 (0.059) | 17.7 - 24.5 (1.8 - 2.5, 13.0 - 18.1) | 48.1 - 65.7 (4.9 - 6.7, 35.4 - 48.5) | 70.6 - 96.1 (7.2 - 9.8, 52.1 - 70.9) |

| M12 | 1.75 (0.068) | 31.4 - 43.1 (3.2 - 4.4, 23.1 - 31.8) | 84.3 - 113.8 (8.6 - 11.6, 62.2 - 83.9) | 123.6 - 167.7 (12.6 - 17.1, 91.1 - 123.7) |

| M14 | 2 (0.078) | 51.0 - 68.6 (5.2 - 7.0, 37.6 - 50.6) | 135.3 - 182.4 (13.8 - 18.6, 99.8 - 134.5) | 198.1 - 268.7 (20.2 - 27.4, 146.1 - 198.2) |

| M16 | 2 (0.078) | 79.4 - 107.9 (8.1 - 11.0, 58.6 - 79.6) | 212.8 - 288.3 (21.7 - 29.4, 157.0 - 212.7) | 311.8 - 421.7 (31.8 - 43.0, 230.0 - 311.0) |

| Flange BOLT/NUT Thin screw | Torque Nm (kg.m, Ib-ft) | |||

Nominal diameter. (mm) |

Pitch [mm (in.) ] | 4T | 8T | 10T |

|

|

|

|

|

|

| M5 | 0.5 (0.019) | 2.9 - 2.9 (0.3 - 0.3, 2.2 - 2.2) | 6.9 - 8.8 (0.7 - 0.9, 5.1 - 6.5) | 9.8 - 13.7 (1.0 - 1.4, 7.2 - 10.1) |

| M6 | 0.75 (0.029) | 3.9 - 5.9 (0.4 - 0.6, 2.9 - 4.3) | 10.8 - 14.7 (1.1 - 1.5, 8.0 - 10.8) | 16.7 - 21.6 (1.7 - 2.2, 12.3 - 15.9) |

| M8 | 1 (0.039) | 9.8 - 12.7 (1.0 - 1.3, 7.2 - 9.4) | 26.5 - 35.3 (2.7 - 3.6, 19.5 - 26.0) | 38.2 - 52.0 (3.9 - 5.3, 28.2 - 38.3) |

| M10 | 1.25 (0.049) | 19.6 - 25.5 (2.0 - 2.6, 14.5 - 18.8) | 51.0 - 68.6 (5.2 - 7.0, 37.6 - 50.6) | 75.5 - 102.0 (7.7 - 10.4, 55.7 - 75.2) |

| M12 | 1.25 (0.049) | 35.3 - 48.1 (3.6 - 4.9, 26.0 - 35.4) | 94.1 - 126.5 (9.6 - 12.9, 69.4 - 93.3) | 138.3 - 186.3 (14.1 - 19.0, 102.0 - 137.4) |

| M14 | 1.5 (0.059) | 55.9 - 75.5 (5.7 - 7.7, 41.2 - 55.7) | 148.1 - 200.1 (15.1 - 20.4, 109.2 - 147.6) | 216.7 - 293.2 (22.1 - 29.9, 159.8 - 216.3) |

| M16 | 1.5 (0.059) | 86.3 - 116.7 (8.8 - 11.9, 63.7 - 86.1) | 229.5 - 309.9 (23.4 - 31.6, 169.3 - 228.6) | 336.4 - 455.0 (34.3 - 46.4, 248.1 - 335.6) |

1)The torques shown in the table are standard values under the following conditions.

• Nuts and bolts are made of galvanized steel bar.

• Galvanized plain steel washers are inserted.

• All nuts, bolts and plain washers are dry.

2)The torques shown in the table are not applicable.

• When spring washers, toothed washers and the like are inserted.

• If plastic parts are fastened.

• If self-tapping screws or self-locking nuts are used.

• If threads and surfaces are coated with oil.

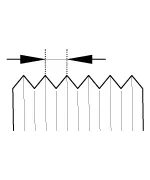

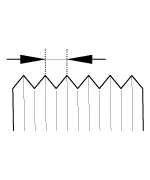

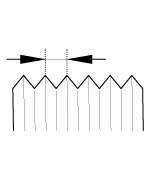

Basic Service Symbols

- Basic Service Symbols There are five primary symbols used to complement illustrations. These symbols indicated the materials to be applied to parts during service.

| Symbol | Meaning |

|

|

Do not reuse the part. Replace a new one. |

|

|

Apply engine oil or transmission oil to the part. |

|

|

Apply automatic transmission fluid (ATF) to the part. |

|

|

Apply grease to the part. |

|

|

Apply sealant to the part. |

General Service Information ➤

Other information:

Hyundai Accent (HC) (2017 - 2022) Service Manual: Integrated Thermal Management Module (ITM)

- Components [Intelligent Variable Transmission (IVT) System] 1. Integrated thermal management module (ITM)2 . Integrated thermal management module (ITM) O-ring3. Heater pipe B4. Heater water hose5. Heater pipe A6 . Heater pipe A gasket7 . Water inlet fitting8 . Water inlet fitting gasket [Manual Transaxle System] 1. Integrated thermal management module (ITM)2 .Hyundai Accent (HC) (2017 - 2022) Service Manual: Repair procedures

- Diagnosis with Diagnostic tool 1.In the body electrical system, failure can be quickly diagnosed by using the vehicle diagnostic system (Diagnostic tool).The diagnostic system (Diagnostic tool) provides the following information.(1)Fault Code Searching : Checking failure and code number (DTC) (2)Data Analysis : Checking the system input/output data state (3)Actuation test : Checking the system operation condition (4)S/W Management : Controlling other features including system option setting and zero point adjustment Data Analysis 1.

Contents

- Important Safety Notice

- Identification Numbers

- Warning and Caution Labels

- Lift and Support Points

- General Tightening Torque Table

- Basic Service Symbols

- General Service Information

Categories

- Manuals Home

- Hyundai Accent Owners Manual

- Hyundai Accent Service Manual

- Questions & Answers

- Video Guides

- Useful Resources

- New on site

- Most important about car

- Privacy Policy

0.0085