Hyundai Accent (HC): Manual Transaxle System (M6CF1)

Hyundai Accent (HC) (2017 - 2022) Service Manual / Manual Transaxle System (M6CF1)

Contents:

- Specifications

- Special Service Tools

- Troubleshooting

- Manual Transaxle System

- Manual Transaxle Control System

Specifications

| Transaxle type | M6CF1 | |

| Engine type | Gasoline 1.6 MPI | |

| Gear ratio | 1st | 3.769 |

| 2nd | 2.045 | |

| 3rd | 1.370 | |

| 4th | 1.036 | |

| 5th | 0.794 | |

| 6th | 0.688 | |

| Reverse | 3.700 | |

| Final gear ratio | 4.267 | |

| Items | N.m | kgf.m | lb-ft |

| Oil drain plug | 58.9 - 78.5 | 6.0 - 8.0 | 43.4 - 57.8 |

| Oil filler plug | 58.9 - 78.5 | 6.0 - 8.0 | 43.4 - 57.8 |

| Shift lever assembly bolt | 8.8 - 13.7 | 0.9 - 1.4 | 9.4 - 10.1 |

| Control cable retainer | 11.8 - 14.7 | 1.2 - 1.5 | 8.7 - 10.8 |

| Back up lamp switch | 39.2 - 58.8 | 4.0 - 6.0 | 28.9 - 43.4 |

| Neutral swtich | 39.2 - 58.8 | 4.0 - 6.0 | 28.9 - 43.4 |

| Control shaft complete | 19.6 - 26.5 | 2.0 - 2.7 | 14.5 - 19.5 |

| Control cable bracket | 14.7 - 21.6 | 1.5 - 2.2 | 10.9 - 15.9 |

| Transaxle bracket mounting bolt | 88.3 - 107.9 | 9.0 - 11.0 | 65.1 - 79.8 |

| Transaxle support bracket mounting bolt | 58.9 - 78.5 | 6.0 - 8.0 | 43.4 - 57.8 |

| Roll rod bracket bolt | 49.0 - 63.7 | 5.0 - 6.5 | 36.2 - 47.0 |

| 107.9 - 127.5 | 11.0 - 13.0 | 79.6 - 94.1 | |

| Roll rod support bracket bolt | 49.0 - 68.6 | 5.0 - 7.0 | 36.2 - 50.6 |

| Start motor mounting bolt | 49.0 - 63.7 | 5.0 - 6.5 | 36.2 - 47.0 |

| Transaxle upper mounting bolt (TM=>ENG) | 42.2 - 53.9 | 4.3 - 5.5 | 31.1 - 39.8 |

| Transaxle lower mounting bolt (ENG=>TM) | 42.2 - 48.1 | 4.3 - 4.9 | 31.1 - 35.4 |

| 42.2 - 53.9 | 4.3 - 5.5 | 31.1 - 39.8 |

| Items | Recommnend lubricant | Quantity | ||||||

| Transaxle gear oil | API Service GL-4, SAE 70W ŌĆó Recommended oil

| 1.5 - 1.6 L (0.40 -0.42 U.S.gal., 1.58 - 1.69 U.S.qt., 1.32- 1.40 lmp qt.) |

| Items | Specified sealant |

| Control shaft assembly | LOCTITE 5060 |

Special Service Tools

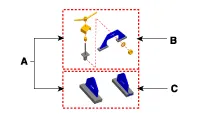

| Tool (Number and name) | Illustration | Use |

| 09200-3N000 Engine support fixture (Beam) |

| Removal and installation of the transaxle. Use this beam (SST No. : 09200-3N000) with the supporter (SST No. : 09200-2S000). ŌĆ╗Permit operating with 09200-38001. |

| A: 09200-2S000 B: 09200-2S100 C: 09200-2S200 Engine support fixture (Supporter) |

| Removal and installation of the transaxle. Use this beam (SST No. : 09200-38001/3N000) with the supporter (SST No. : 09200-2S000). |

| 09431-26100 Oil seal installer |

| Installation of the differential oil seal in the transaxle case and housing side. [Using with handle (SST No.09231-H1100)] |

| 09231-H1100 Bar |

| Installation of the differential oil seal in the transaxle case and housing side. [Using with oil seal installer (SST No.:09431-26100)] |

Troubleshooting

| Symptom | Suspected Area | Remedy |

| Abnormal noise | Oil level (Low) | To adding oil after inspect the parts (Oil seal, Drain plug, filler plug). |

| Oil (Wrong) | Replace the oil. | |

| Synchronizer ring (Worn or damaged) | Replace the synchronizer ring. | |

| Gear (Worn or damaged) | Replace the gear. | |

| Bearing (Worn or damaged) | Replace the bearing. | |

| Oil leak | Oil level (High) | Inspect the oil level. |

| Gasket (Damaged) | Replace the gasket. | |

| Oil seal (Worn or damaged) | Replace the oil seal. | |

| Hard shifting or impossible to shift | Oil (Wrong) | Replace the oil. |

| Clutch (Dragging) | Inspect the clutch parts (Release fork & bearing, Clutch disc) | |

| Shift fork (Worn) | Replace the shift fork. | |

| Synchronizer ring (Worn or damaged) | Replace the synchronizer ring. | |

| Gear (Worn or damaged) | Replace the gear. | |

| Hub sleeve (Worn or damaged) | Replace the hub sleeve. | |

| Jumps out of gear or shift lever moves excessively | Shift fork (Worn) | Replace the shift fork. |

| Hub sleeve (Worn or damaged) | Replace the hub sleeve. | |

| Gear (Worn or damaged) | Replace the gear. | |

| Bearing (Worn or damaged) | Replace the bearing. |

Manual Transaxle System ➤

Manual Transaxle Control System ➤

Other information:

Forward Collision-Avoidance Assist is designed to help reduce or help avoid accident risk. It recognizes the distance to the vehicle ahead through sensors (for example, radar), and, if necessary, warns the driver or applies emergency braking. ŌØł Radar type FCA does not recognize for pedestrians in front. WARNING Forward Collision-avoidance Assist is a supplemental system and is not a substitute for safe driving practices.Information - Using MP3 on the Hyundai Accent: This media section explains how your Hyundai Accent audio system handles common music files and what to expect when browsing tracks. Supported audio formats: The Hyundai Accent multimedia unit is designed to play popular formats for everyday listening, provided the files meet the requirements shown below.

Contents

- Specifications

- Special Service Tools

- Troubleshooting

- Manual Transaxle System

- Manual Transaxle Control System

Categories

- Manuals Home

- Hyundai Accent Owners Manual

- Hyundai Accent Service Manual

- Questions & Answers

- Video Guides

- Useful Resources

- New on site

- Most important about car

- Privacy Policy

Copyright ┬® 2026

0.0078

0.0078