Hyundai Accent (HC): Emission Control System / Evaporative Emission Control System

Contents:

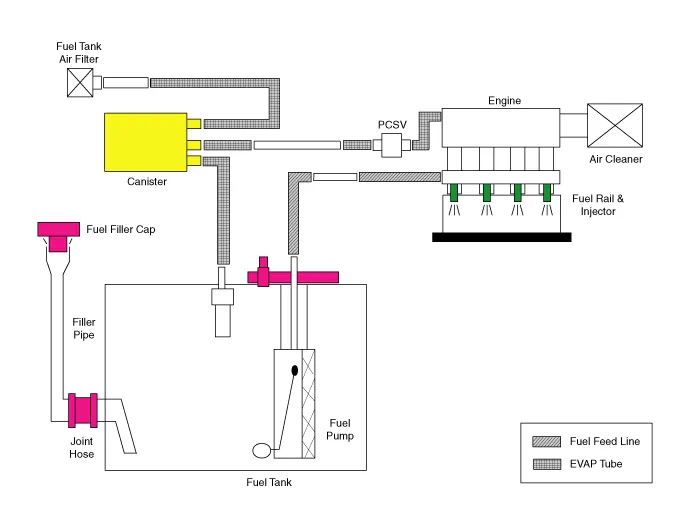

Schematic Diagrams

Repair procedures

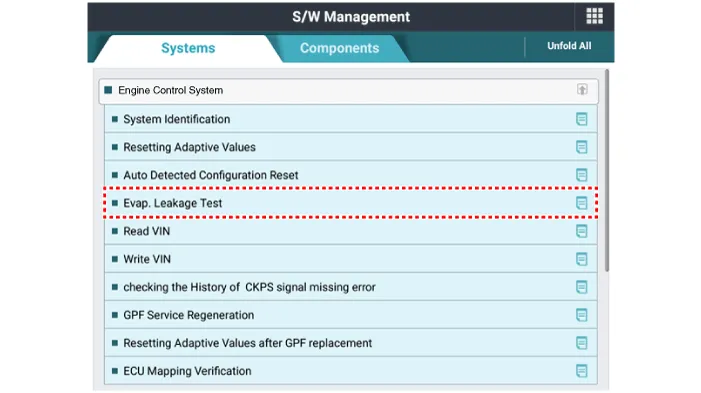

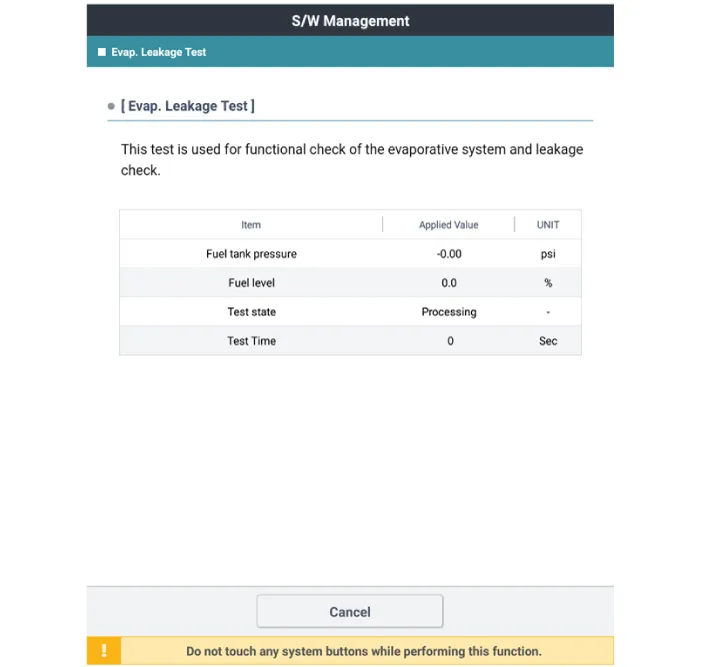

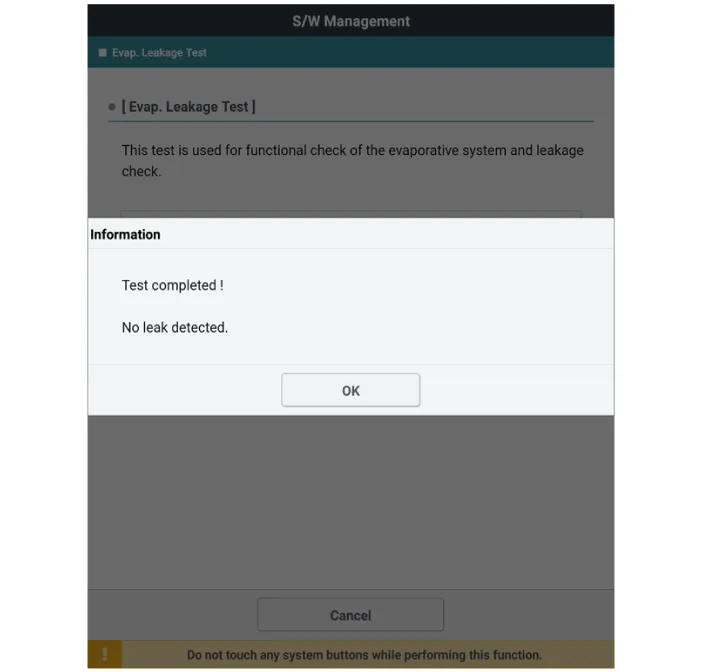

1.Select "Evap. Leakage Test".

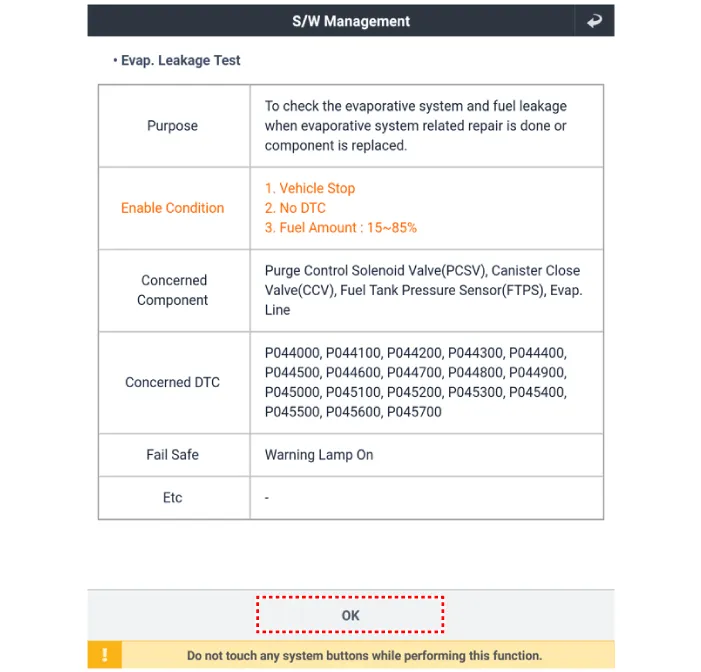

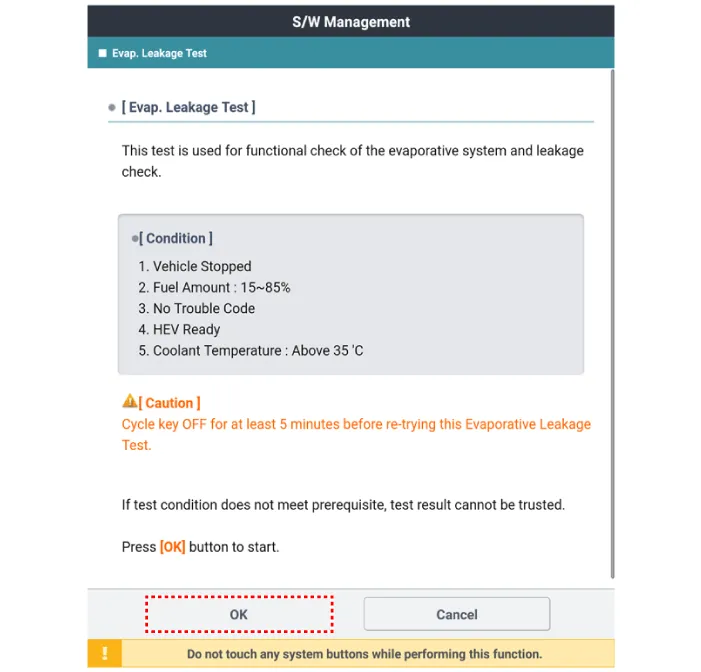

2.The test shall be conducted in accordance with GDS instructions.

Canister

1.Turn the ignition switch OFF and disconnect the battery negative (-) cable.

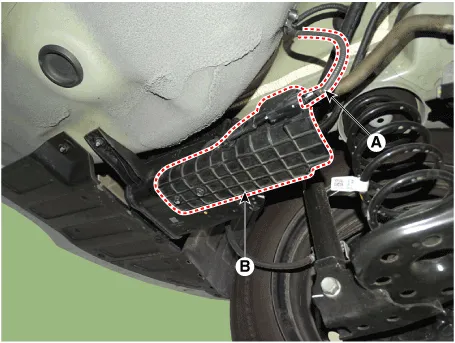

2.Lift the vehicle.

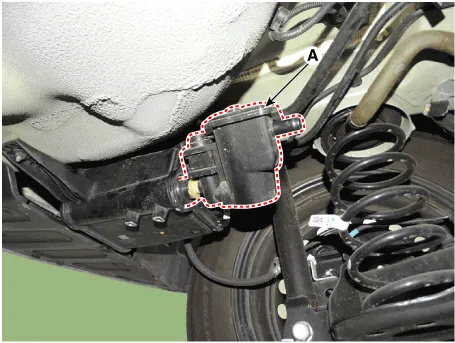

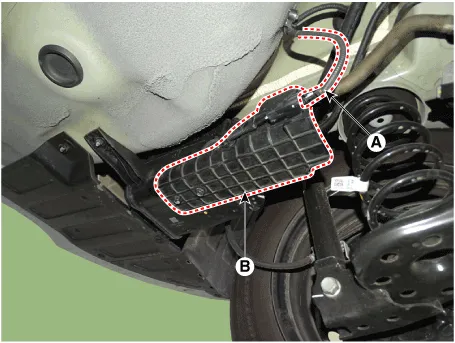

3.Disconnect the canister close velve extension connector (A).

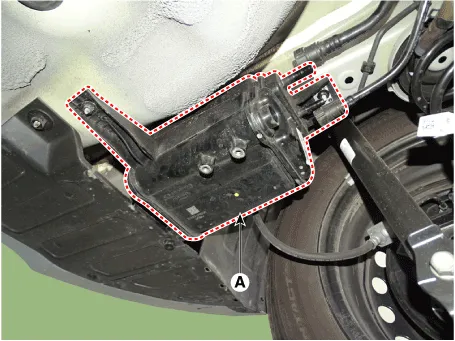

4. Remove the canister protector (B).

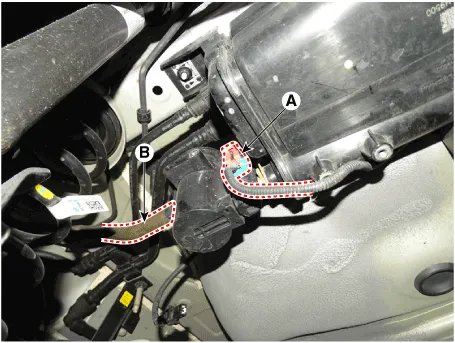

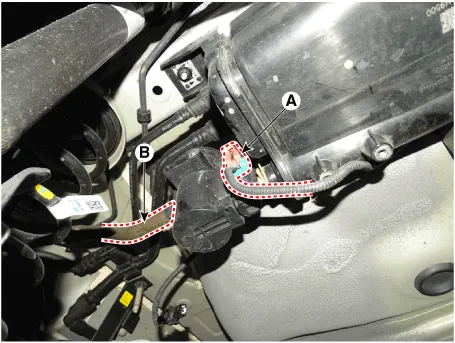

5.Disconnect the canister close velve connector (A).

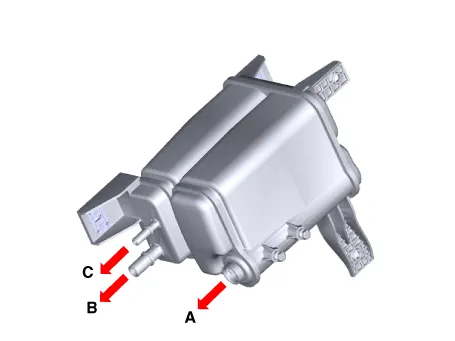

6.Remove the ventilation hose (B).

7.Remove the air filter (A).

8.Disconnect the vapor hose quick-connector (A).

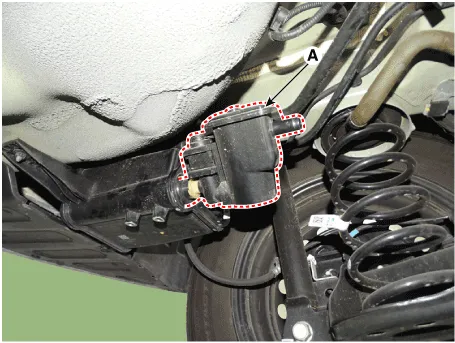

9.Remove the canister assembly (A) after loosening the bolt and nut.

Canister installation bolt :19.6 - 29.4 N.m (2.0 - 3.0 kgf.m, 14.5 - 21.7 lb-ft)

1.Check for the following items visually.

– Cracks or leakage of the canister

– Loose connection, distortion, or damage of the vapor hose/ tube

1.Install in the reverse order of removal.

Fuel Filler Cap

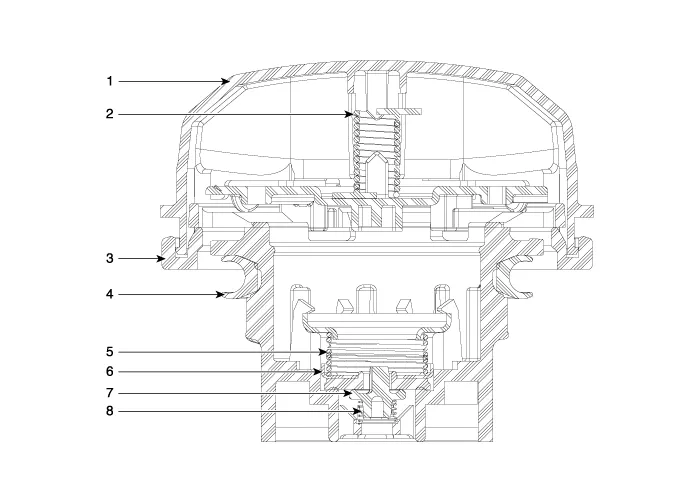

1. Cover

2. Torsion spring

3. Retainer

4. Gasket seal

5. Spring

6. Plate seal

7. Vacuum valve

8. Spring

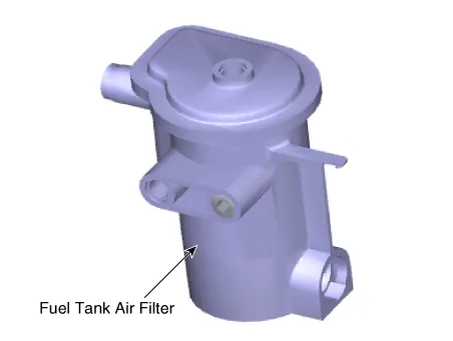

Fuel Tank Air Filter

1.Turn the ignition switch OFF and disconnect the battery negative (-) cable.

2.Lift the vehicle.

3.Disconnect the canister close velve extension connector (A).

4. Remove the canister protector (B).

5.Disconnect the canister close velve connector (A).

6.Remove the ventilation hose (B).

7.Remove the air filter (A).

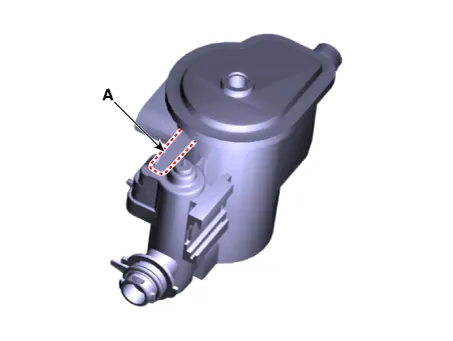

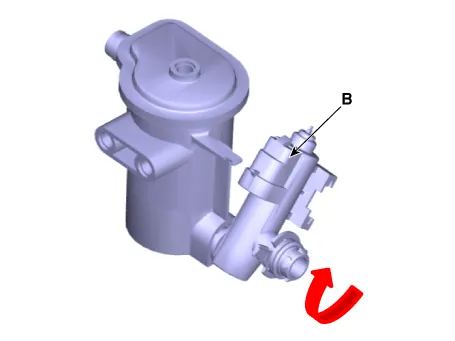

8.Release the lever (A), and then separate the canister close valve (B) from the fuel tank air filter after rotating it in the direction of the arrow in the figure.

Other information:

Hyundai Accent (HC) (2017 - 2022) Service Manual: Instrument cluster

â– Type A â– Type B 1. Tachometer 2. Speedometer 3. Engine coolant temperature gauge 4. Fuel gauge 5.Warning and indicator lights 6. LCD display (including Trip computer)Hyundai Accent (HC) (2017 - 2022) Service Manual: Repair procedures

- Refrigerant System Service Basics Refrigerant Identification • Do not mix R-1234yf in the vehicle with other refrigerant, such as R-134a and etc. • Use only service equipment that is U.L-listed and is certified to meet the requirements of SAE standards to recover and recycle R-1234yf from the air conditioning system. Do not use service equipment for the other refrigerant, such as R-134a and etc.

Contents

Categories

- Manuals Home

- Hyundai Accent Owners Manual

- Hyundai Accent Service Manual

- Questions & Answers

- Video Guides

- Useful Resources

- New on site

- Most important about car

- Privacy Policy

0.0132