Hyundai Accent (HC): Suspension System / Tires/Wheels

Contents:

Tire

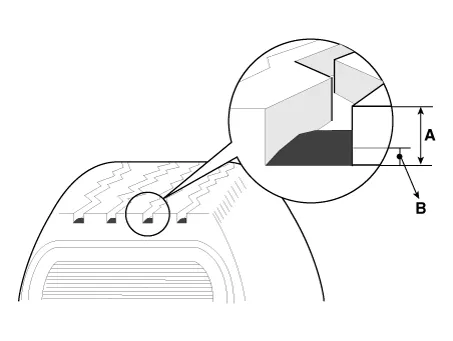

1.Measure the tread depth of the tires.

Tread depth [limit] : 1.6 mm (0.063 in)

2.If the remaining tread depth (A) is less than the limit, replace the tire.

• When the tread depth of the tires is less than 1.6 mm(0.063 in), the wear indicators (B) will appear.

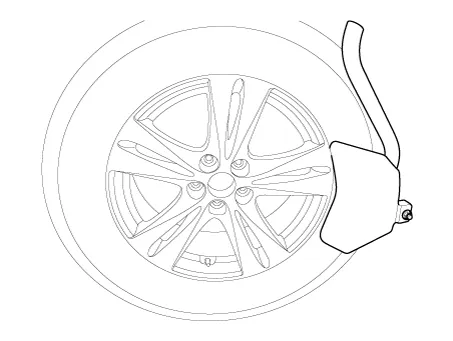

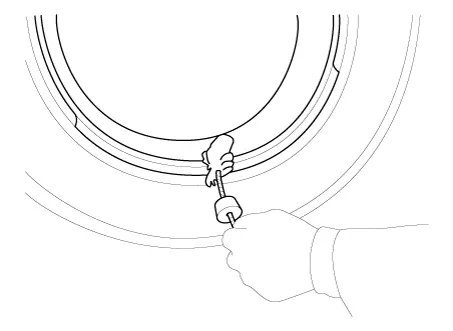

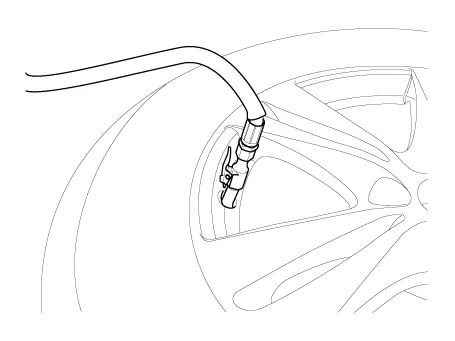

1.Remove valve core and deflate the tire.

2.Remove the side of the tire bead area from the wheel using tire changing machine.

• The tire bead should be broken approx. 90° from the valve side of the wheel. The bead breaker should not be set too deep.

• Avoid tire / tool contact with the valve on dismount.

• Dismount should end near the valve.

3. Rotate the wheel clockwise.

1. Apply tire soap or lubrication to the top and bottom tire beads.

2.To fit the bottom bead, position the valve at the 5 o’clock position relative to the head on the tire changing machine.

3. Place the tire on the rim so the bottom bead touches the edge of the rim after the valve (6 o’clock). Rotate the rim clockwise, and push down on the tire at the 3 o’clock position to fit bottom bead.

4.After bottom bead is on tire, rotate the rim until the valve is at the 5 o’clock position relative to the head on the tire changing machine. Push down on the tire at the 3 o’clock position and rotate the rim clockwise to fit the top bead.

5.Inflate the tire until both beads seat.

Recommended Tire pressure : 230 kPa (33 psi)

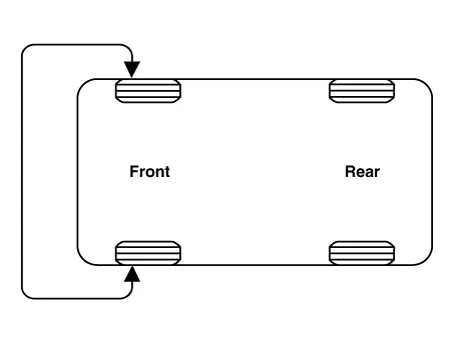

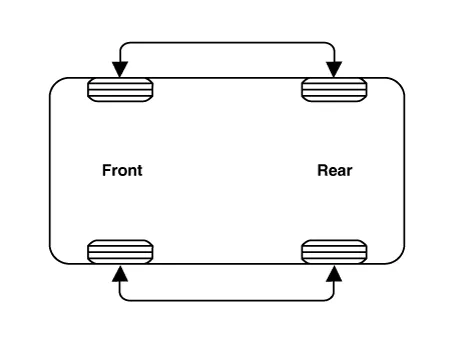

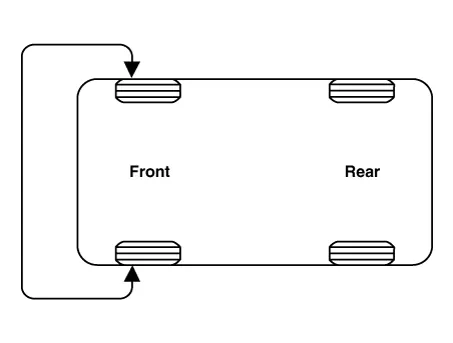

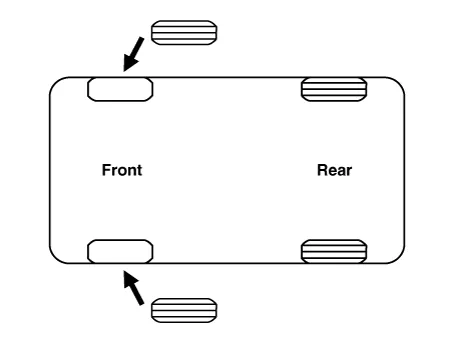

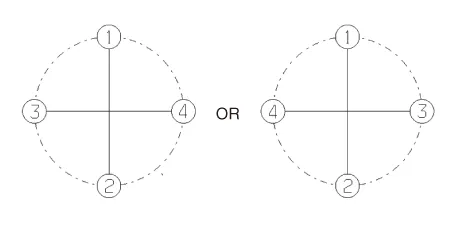

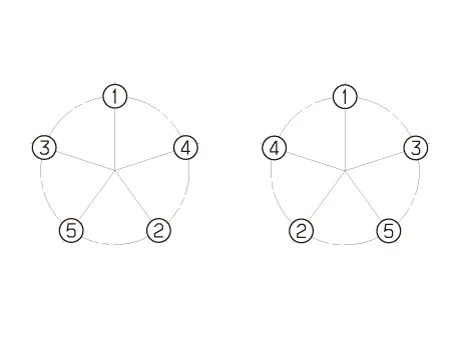

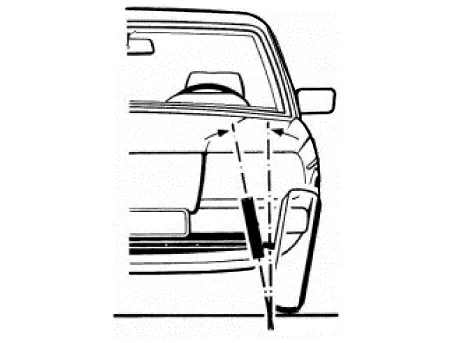

1.Rotate the front right and front left tires, and perform a road test in order to confirm vehicle stability.

2.If the steering pulls to the opposite side, rotate the front and rear tires, and perform a road test again.

3.If the steering continues to pull to one side, rotate the front right and left tires again, and perform a road test.

4.If the steering continues to pull to the opposite side, replace the front wheels with new ones.

Wheel

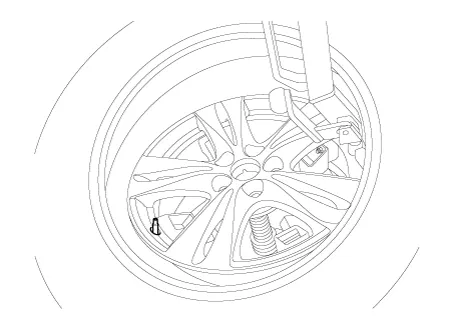

1.Tighten the hub nuts as follows.

Tightening torque :107.9 - 127.5 N.m (11.0 - 13.0 kgf.m, 79.6 - 94.0 lb-ft)

• When using an impact gun, final tightening torque should be checked using a torque wrench.

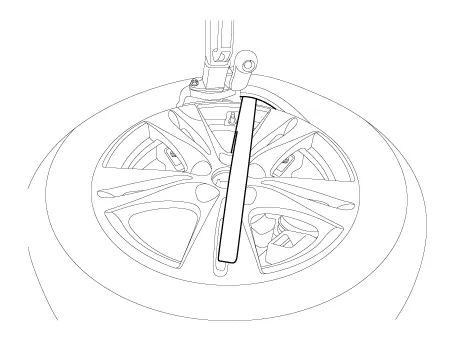

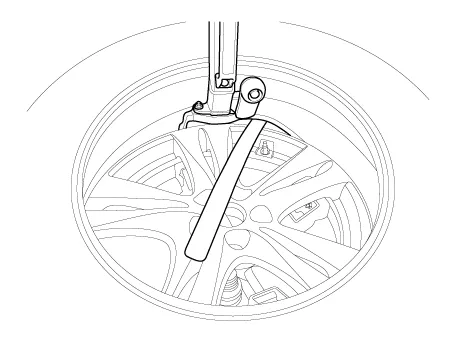

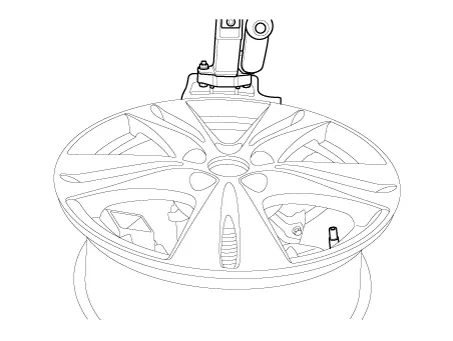

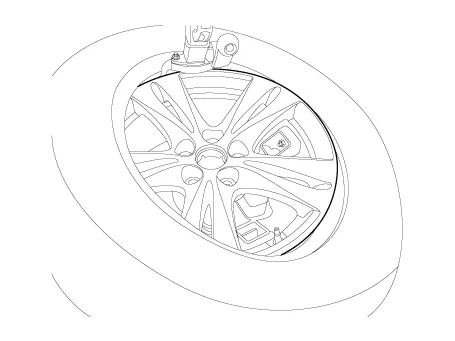

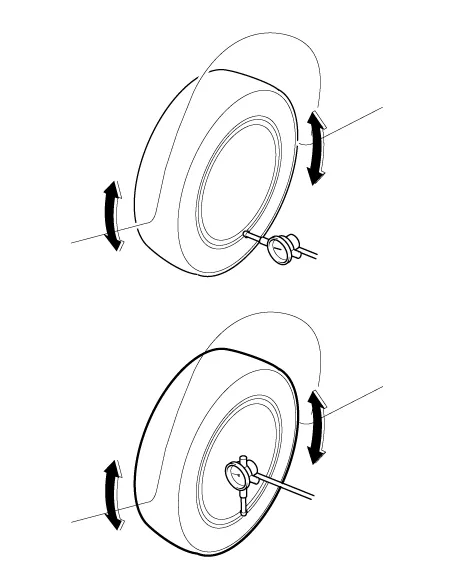

1.Jack up the vehicle.

2.Measure the wheel Run-out by using a dial indicator as illustration below.

| Run-out | Aluminum |

| Radial mm (in.) | Below 0.3 (0.0118) |

| Lateral mm (in.) | Below 0.3 (0.0118) |

3.If measured value exceeds the standard value, replace the wheel.

Alignment

• When using a commercially available computerized wheel alignment equipment to inspect the front wheel alignment, always position the vehicle on a level surface with the front wheels facing straight ahead.

• Prior to inspection, make sure that the front suspension and steering system are in normal operating condition and that the tires are inflated to the specified pressure.

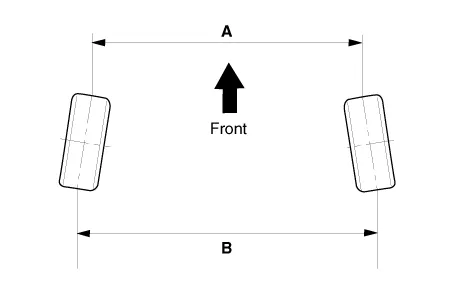

B - A > 0 : Toe in (+)B - A < 0 : Toe out (-)

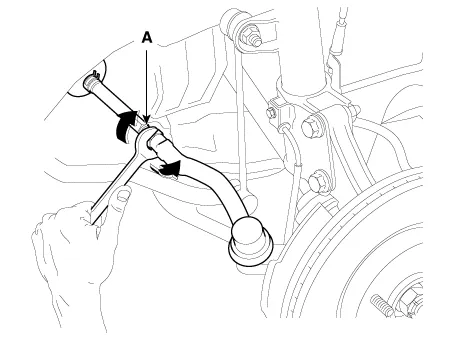

1.Loosen the tie rod end lock nut.

2.Remove the bellows clip to prevent the bellows from being twisted.

3.Adjust the toe by screwing or unscrewing the tie rod. Toe adjustment should be made by turning the right and left tie rods by the same amount.

Toe-inTotal : 0.15˚ ± 0.2˚Individual : 0.075˚ ± 0.1˚

4.When completing the toe adjustment, install the bellows clip and tighten the tie rod end lock nut to specified torque.

Tightening torque :49.0 - 53.9 N.m (5.0 - 5.5 kgf.m, 36.2 - 39.8 lb-ft)

| Camber angle | -0.5˚ ± 0.5˚ |

Caster angle : 4.64˚ ± 0.5˚

King-pin : 13.23˚ ± 0.5˚

• The worn loose or damaged parts of the front suspension assembly must be replaced prior to measuring front wheel alignment.

• Caster are pre-set to the specified value at the factory and don't need to be adjusted.

• If the caster are not within specifications, replace bent or damaged parts.

• The difference of left and right wheels about the the caster must be within the range of 0° ± 0.5°.

• When using a commercially available computerized wheel alignment equipment to inspect the rear wheel alignment, always position the vehicle on a level surface.

• Prior to inspection, make sure that the rear suspension system is in normal operating condition and that the tires are inflated to the specified pressure.

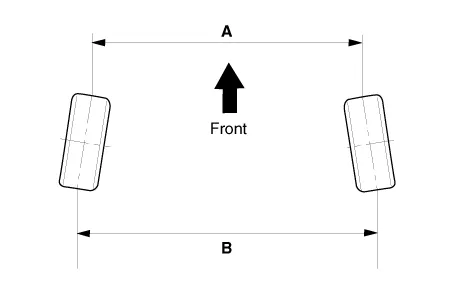

B - A > 0 : Toe in (+)B - A < 0 : Toe out (-)

Toe is pre-set at the factory, so it does not need to be adjusted. If the toe is not within the standard value, replace or repair the damaged parts and then inspect again.| Toe-in | Total | 0.3° ± 0.3° |

| Individual | 0.15° ± 0.15° |

Camber angle : -1.5˚ ± 0.5˚

Other information:

Hyundai Accent (HC) (2017 - 2022) Service Manual: Inside Rearview Mirror

Before you start driving, adjust the inside rearview mirror to center the view through the rear window. A correctly adjusted mirror in your Hyundai Accent helps you maintain safe awareness of traffic behind you without needing to change your seating position. WARNING Make sure your line of sight is not obstructed. Do not place objects in the rear seat, cargo area, or behind the rear headrests that could interfere with your vision through the rear window.Hyundai Accent (HC) (2017 - 2022) Service Manual: Specifications

- Specifications DescriptionSpecificationsLimit General TypeIn-line, DOHC   Number of cylinders4   Bore75.60 mm (2.9764 in)   Stroke89.0 mm (3.5039 in.)  Total displacement1,598 cc (97.52 cu.in)  Compression ratio11.2 ± 0.2 : 1  Firing order1-3-4-2   Valve timing Intake valveOpensBTDC 42° - ATDC 38°   ClosesABDC 7° - ABDC 87°   Exhaust valveOpensBBDC 43° - ABDC 2°   ClosesATDC 0° - ATDC 45°   Cylinder head Flatness of gasket surfaceLess than 0.

Contents

Categories

- Manuals Home

- Hyundai Accent Owners Manual

- Hyundai Accent Service Manual

- Questions & Answers

- Video Guides

- Useful Resources

- New on site

- Most important about car

- Privacy Policy

0.0108