Hyundai Accent (HC): Manual Transaxle System (M6CF1) / Manual Transaxle Control System

Contents:

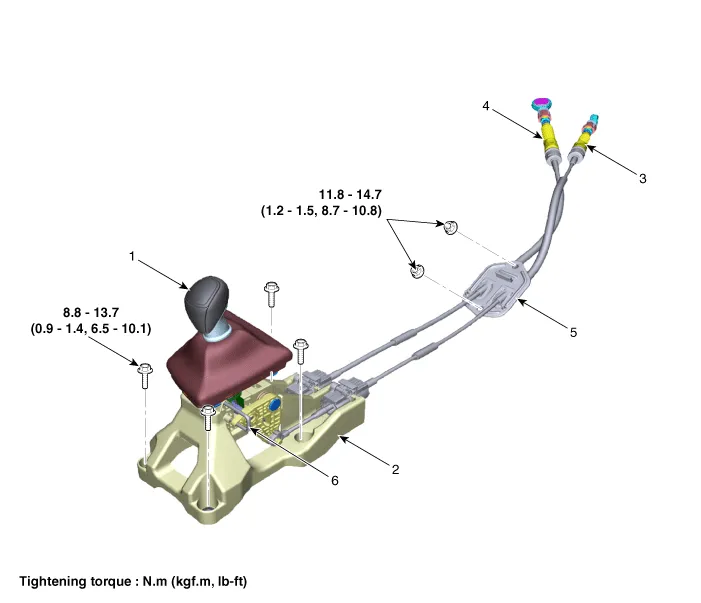

Shift Lever

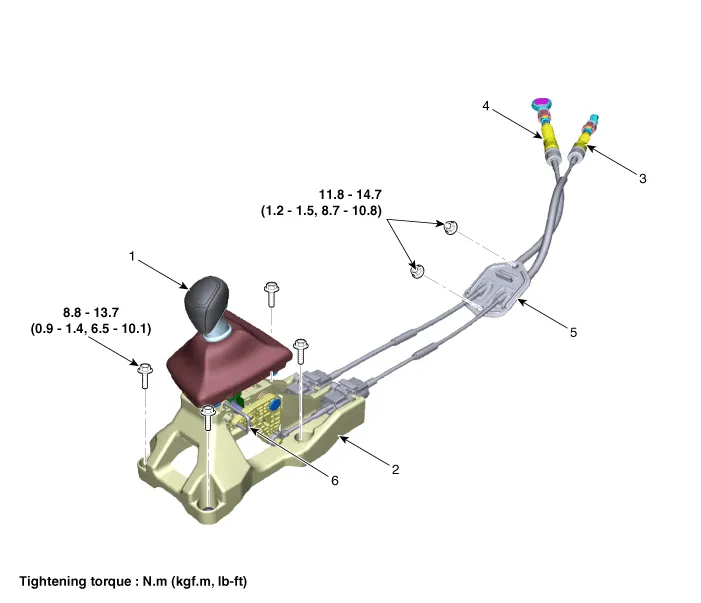

1. Shift lever knob & boots

2. Shift lever assembly

3. Select cable

4. Shift cable

5. Retainer

6. 4th fixing pin

1.Turn OFF ignition switch and disconnect the negative (-) battery cable.

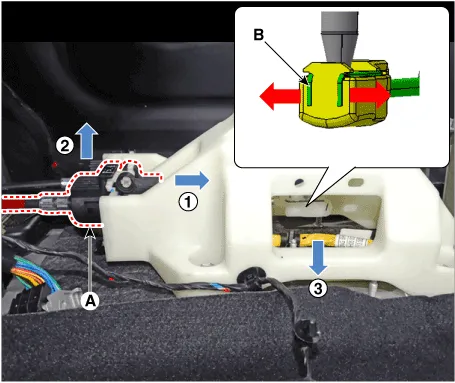

2. Remove the shift lever knob & boots (A) pull both of it up.

3.Remove the floor console assembly. (Refer to Body - "Floor Console")

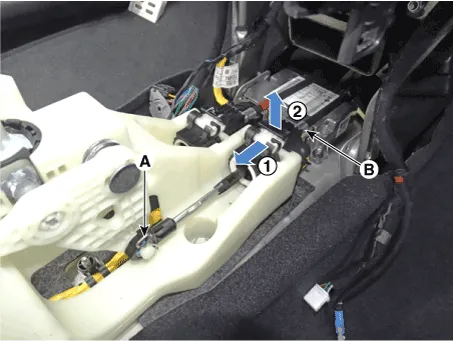

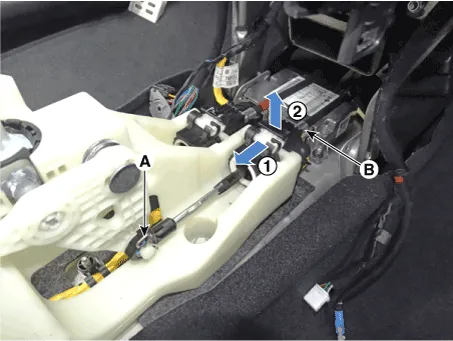

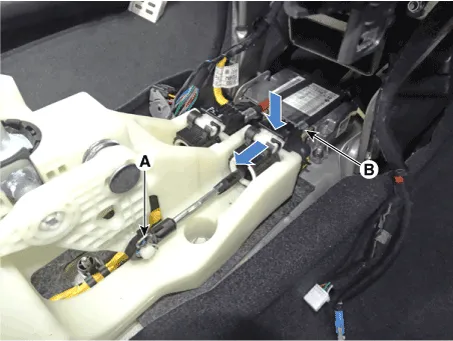

4.Separate the select cable (B), after removing the snap pin (A).

5. Remove the shift cable.

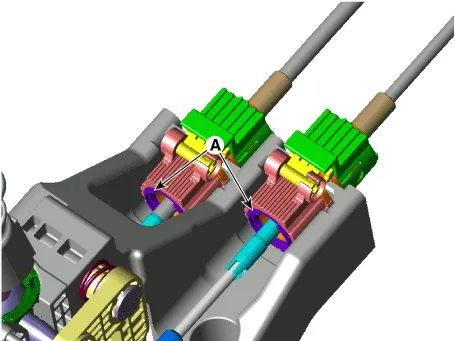

(1)Remove the cable socket (A), after release the lock.

(2)Remove the clip, in the shape of a "U"(B), from the cable end by spreading it towards both sides.

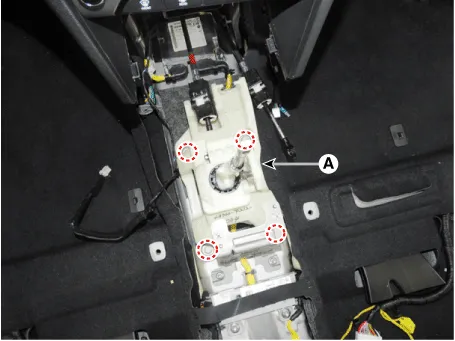

6.Loosen the bolts and then removing the shift lever (A).

Tightening torque :8.8 - 13.7 N.m (0.9 - 1.4 kgf.m, 6.5 - 10.1 lb-ft)

1.To install, reverse the removal procedures.

• New shift lever assembly is mounted in the 4th fixing pin.After installation, remove the 4th fixed pin.

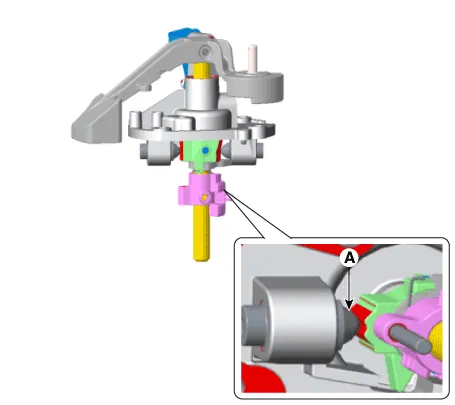

• After installing the select cable and shift cable socket, check portion (A) to see if it projects outwards from the cap.

• Check operating of lever of transaxle side when operating shift lever after assembly. (1~6,R)

• If there is sticky feel, adjust the control cable length again.(Refer to Control Cable - "Installation")

Control Cable

1. Shift lever knob & boots

2. Shift lever assembly

3. Select cable

4. Shift cable

5. Retainer

6. 4th fixing pin

1.Move the shift lever to 4th gear.

2.Turn OFF ignition switch and disconnect the negative (-) battery cable.

3.Remove the air cleaner assembly and air duct.(Refer to Engine Mechanical System - "Air Cleaner")

4.Remove the battery and battery tray.(Refer to Engine Electrical System - "Battery")

5.Remove the Engine Control Module (ECM).(Refer to Engine Control System - "ECM")

6.Separate the control cable.

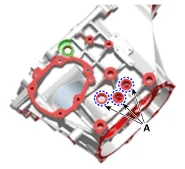

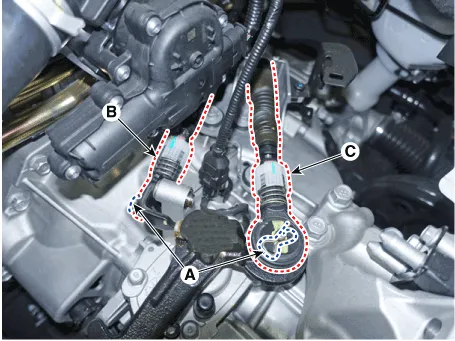

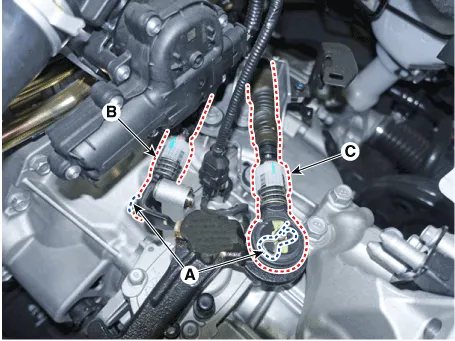

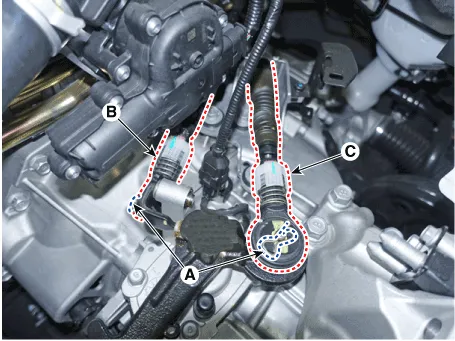

1)Remove the snap pin (A).

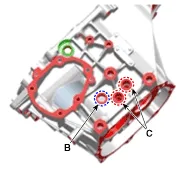

2)Separate the select cable (B) and then shift cable (C).

7.Remove the shift knob & boot (A).

8.Remove the floor console assembly. (Refer to Body - "Floor Console")

9.Separate the select cable (B), after removing the snap pin (A).

10.Remove the shift cable.

(1)Remove the cable socket (A), after release the lock.

(2)Remove the clip, in the shape of a "U"(B), from the cable end by spreading it towards both sides.

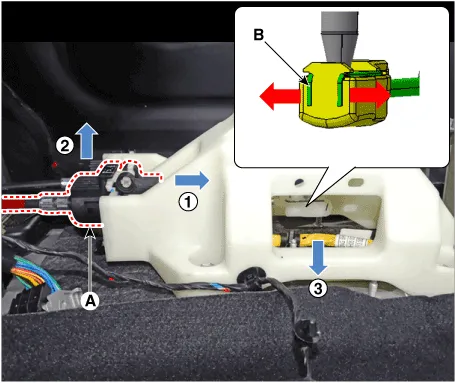

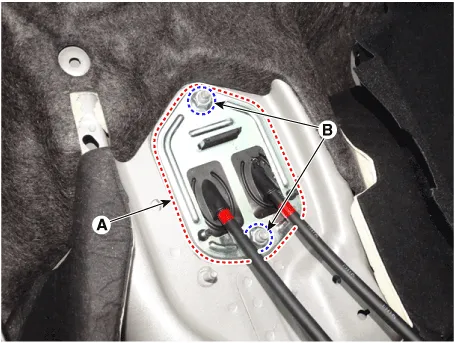

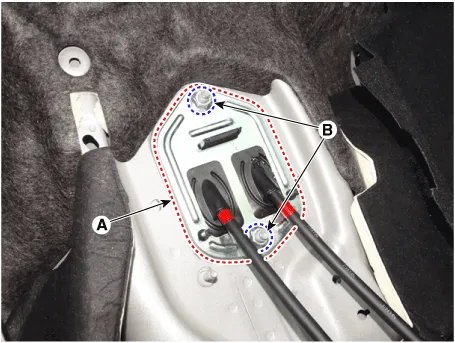

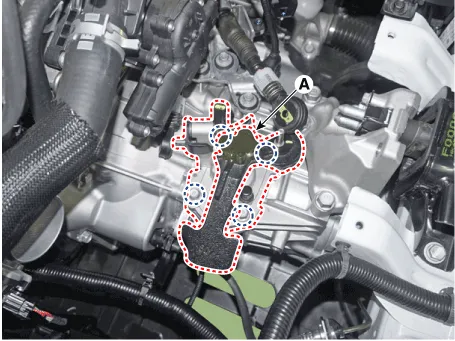

11.Loosen the nuts and then removing the retainer (A).

12.Remove the control cable assembly (A) from the vehicle.

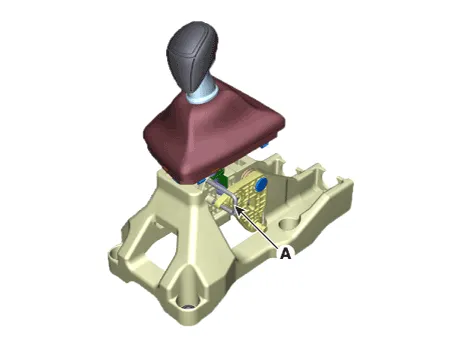

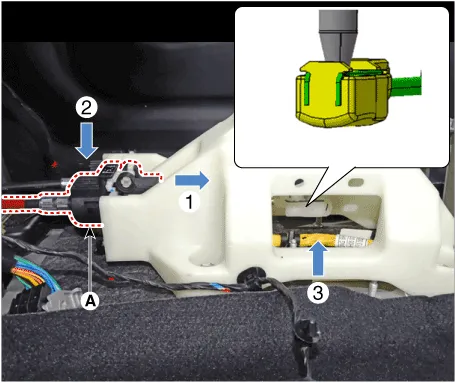

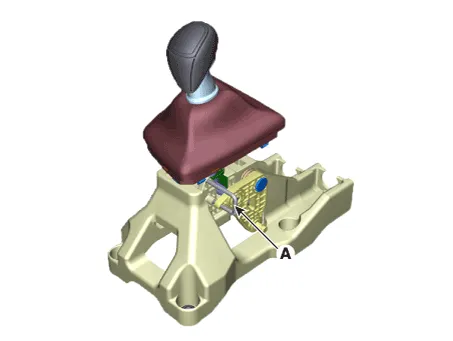

• Place the shift lever and transaxle side lever in 4th shift position and insert the lever fixing pin (A).

1.Install the retainer (A) and then tighten the nuts (B).

Tightening torque :11.8 - 14.7 N.m (1.2 - 1.5 kgf.m, 8.7 - 10.8 lb-ft)

2. Install the select cable (B), and then fixing the snap pin (A).

3.Install the shift cable (A).

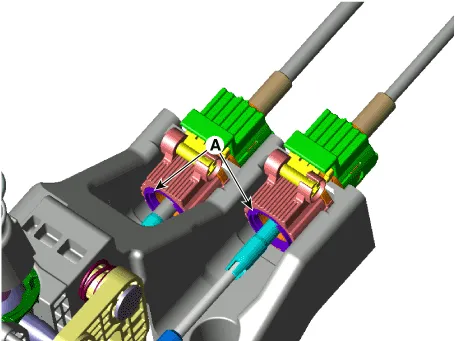

• After installing the select cable and shift cable socket, check portion (A) to see if it projects outwards from the cap.

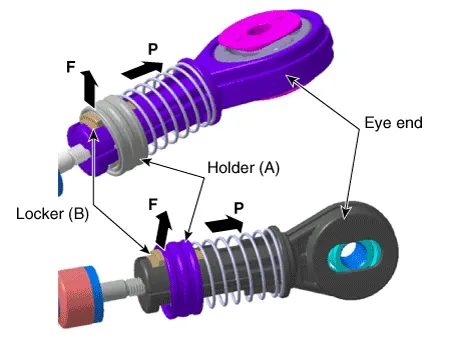

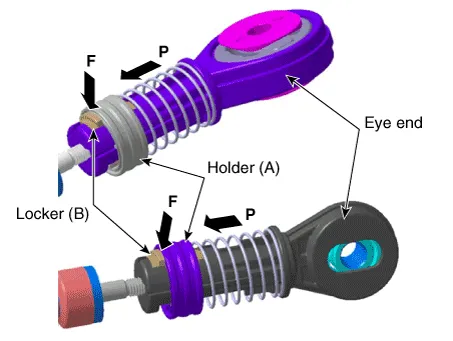

4.Move the locker (B) in the direction of "F" with pulling the holder (A) in the direction of "P".

5. Install the control cable.

1)Install the snap pin (A).

2) Separate the select cable (B) and then shift cable (C).

6.Tighten the holder (A) to the "P" directions after fixing the rockers (B) in the "F" direction.

7.Remove the shift lever 4th fixed pin (A).

8.Install the floor console assembly.(Refer to Body - "Floor Console")

9.Install the battery and battery tray.(Refer to Engine Electrical System - "Battery")

10.Install the engine control module (ECM).(Refer to Engine Control System - "ECM")

11. Install the air cleaner assembly and air duct.(Refer to Engine Mechanical System - "Air Cleaner")

• Check operating of lever of transaxle side when operating shift lever after assembly. (1~6,R)

• If there is sticky feel, adjust the control cable length again.(Refer to Control Cable - "Installation")

Control Shaft Complete

1. Control shaft complete

1.Set shift lever to N position.

2.Turn OFF ignition switch and disconnect the negative (-) battery cable.

3.Remove the air cleaner assembly and air duct.(Refer to Engine Mechanical System - "Air Cleaner")

4.Remove the battery and battery tray.(Refer to Engine Electrical System - "Battery")

5.Remove the engine control module (ECM).(Refer to Engine Control System - "ECM")

6.Separate the control cable.

1)Remove the snap pin (A).

2)Separate the select cable (B) and then shift cable (C).

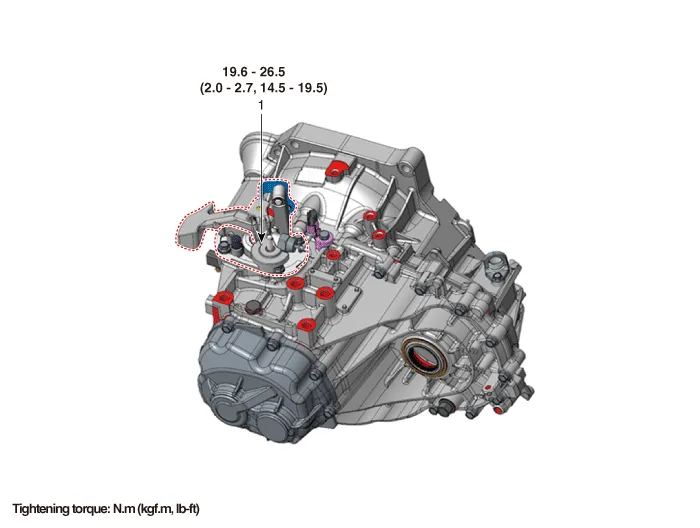

7.Remove the control shaft assembly (A) after loosening the bolts.

Tightening torque :19.6 - 26.5 N.m (2.0 - 2.7 kgf.m,14.5 - 19.5 lb-ft)

1.To install, reverse the removal procedures.

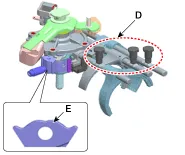

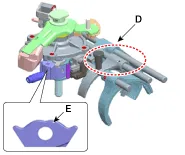

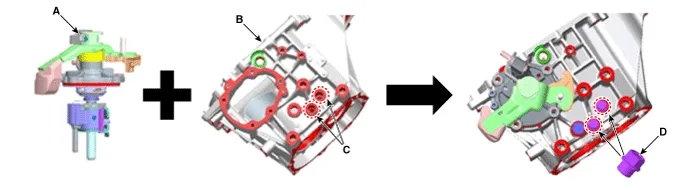

1)Main changes of the M/T case- A : 3 poppet ball taps- B : 1 poppet ball tap for 5th/6th shift rail- C : 2 poppet ball taps for (1st/2nd, 3rd/4th) shift rails have been deleted.- D : The number of poppet balls has been reduced from 3EA to 1EA and the grooves on the 1st/2nd, 3rd/4th shift rails have been deleted.- E : The shift groove of control finger has been changed in shape.

| M/T type | Previous | New |

| Case |

|

|

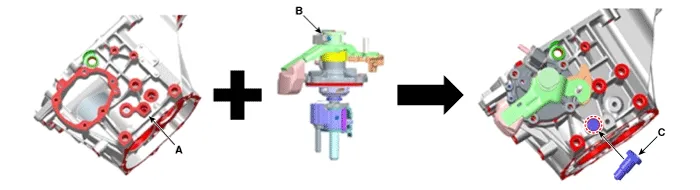

| Control Shaft Complete |

|

|

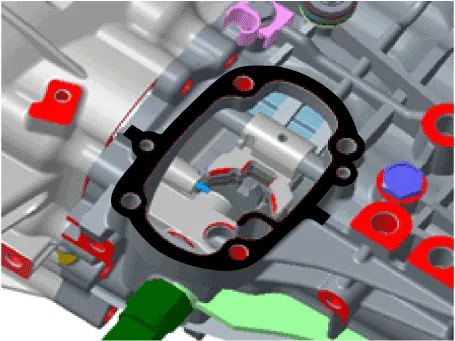

2)When trying to replace the previously designed control shaft complete with a newly designed one from the previously designed M/T case. - Replace with a newly designed control shaft complete (A), Remove the poppet ball (C-2ea) for 1st/2nd, 3rd/4th shift rails from the previously designed M/T case (B) and then assemble the seal bolt (D-2ea) to that position.

3)When trying to replace the previously designed M/T case with a newly designed one. - Be sure to also replace the previously designed control shaft complete (B) with A newly designed one as well as the M/ T case (A).- Assemble poppet bolt (C-1ea) to the newly designed M/T case (A) (Previous: 3ea).

• When installing, set control shaft lever to neutral position (A).

• Apply the sealant to the contact surface of transaxle and control shaft.

Specified sealant : LOCTITE 5060

2.After installing, check to be sure that this part operates as designed at each range of transaxle side corresponding to each position of shift lever.

Other information:

Hyundai Accent (HC) (2017 - 2022) Service Manual: General Information

- General Troubleshooting Information Before Troubleshooting 1.Check applicable fuses in the appropriate fuse/relay box. 2.Using the battery checker (MCR-570 KIT), check the battery for damage, state of charge, and clean and tight connections.(Refer to Engine Electrical System - "Battery") • Do not quick-charge a battery unless the battery ground cable has been disconnected, otherwise you will damage the alternator diodes.Hyundai Accent (HC) (2017 - 2022) Service Manual: Manual Heating and Air Conditioning

You can also operate the heating and cooling system manually by pressing buttons other than AUTO. In this mode, the system follows your selections in sequence, while functions you do not adjust may still be managed automatically. When pressing any button except the AUTO button while using automatic operation, the functions not selected will be controlled automatically.

Contents

Categories

- Manuals Home

- Hyundai Accent Owners Manual

- Hyundai Accent Service Manual

- Questions & Answers

- Video Guides

- Useful Resources

- New on site

- Most important about car

- Privacy Policy

0.0091