Hyundai Accent (HC): Engine Electrical System / Ignition System

Contents:

Description and Operation

Repair procedures

Inspect ignition coil assembly and Perform spark test

1.Check for DTCs.

• If a DTC is present, perform troubleshooting in accordance with the procedure for that DTC. (Refer to DTC guide)

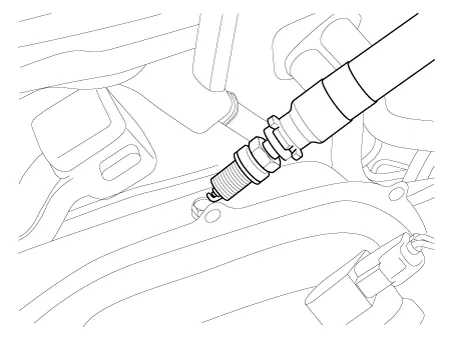

2.Check if sparks occur.

(1)Remove the engine cover.

(2)Remove the ignition coils.

(3)Using a spark plug wrench, remove the spark plugs.

(4)Disconnect the 4 injector connectors.

(5) Ground the spark plug to the engine.

(6)Check if sparks occur at each spark plug while engine is being cranked.

• Do not crank the engine for more then 5 seonds.

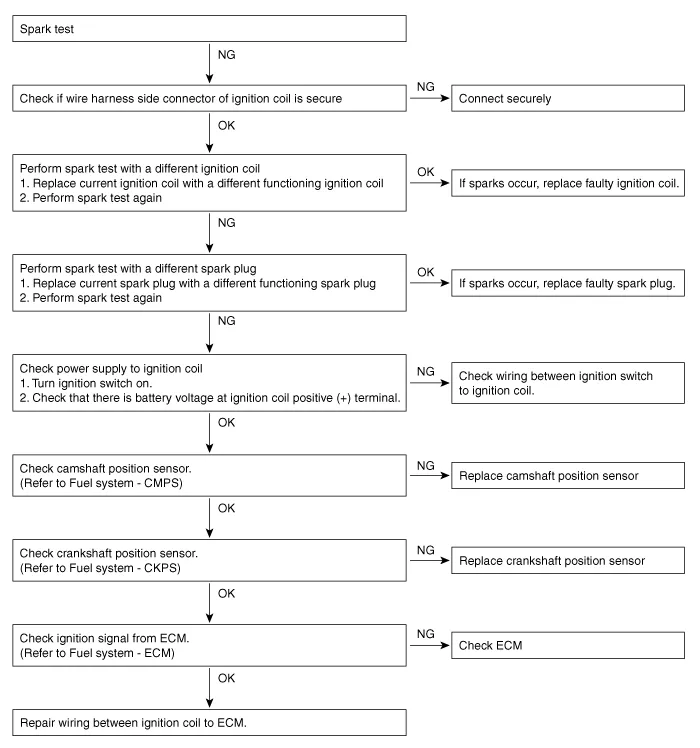

3. If sparks do not occur, perform the following test.

4.Using a spark plug wrench, install spark plugs.

5.Install the ignition coils.

6.Install the engine cover.

Troubleshooting

| Symptom | Suspect Area | Remedy |

| Engine will not start or is hard to start (Cranks OK) | Ignition lock switch | Inspect ignition lock switch, or replace as required |

| Ignition coil | Inspect ignition coil, or replace as required | |

| Spark plugs | Inspect spark plugs, or replace as required | |

| Ignition wiring disconnected or broken | Repair wiring, or replace as required | |

| Rough idle or stalls | Ignition wiring | Repair wiring, or replace as required |

| Ignition coil | Inspect ignition coil, or replace as required | |

| Engine hesitates / poor acceleration | Spark plugs and spark plug cables | Inspect spark plugs / cable, or replace as required |

| Ignition wiring | Repair wiring, or replace as required | |

| Poor mileage | Spark plugs and spark plug cables | Inspect spark plugs / cable, or replace as required |

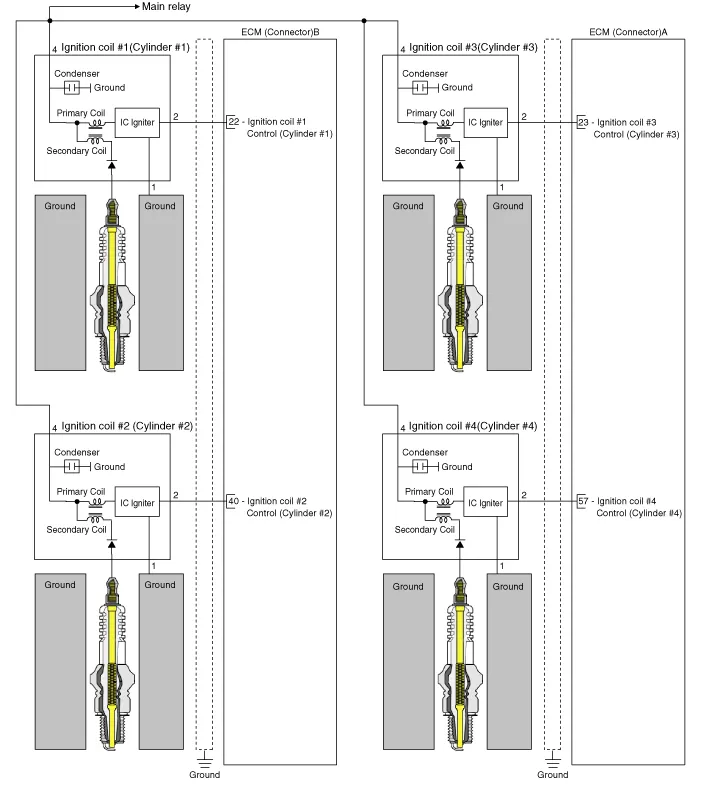

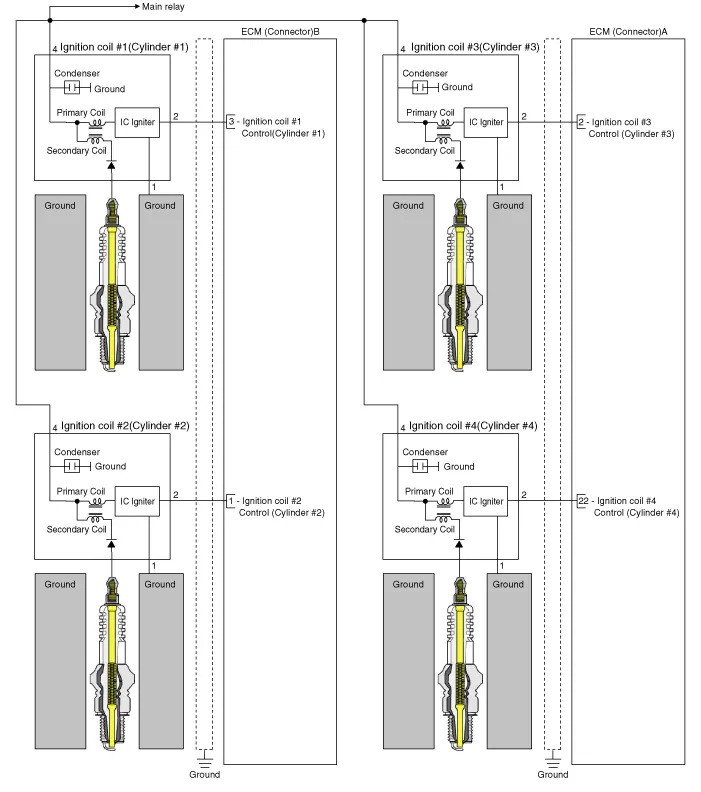

Ignition Coil

| Item | Specification |

| Rated Voltage (V) | 13.5 |

| Operation Voltage (V) | 6 - 16 |

| Item | Specification | |||||

| Engine Speed (RPM) | 1000 | 2000 | 3000 | 4000 | 5000 | 6000 |

| Dwell Time (ms) | 3.4 | 3.4 | 3.4 | 2.9 | 2.7 | 2.5 |

| Secondary Coil Voltage (kV) | 40 ↑ | 40 ↑ | 40 ↑ | 40 ↑ | 40 ↑ | 38 ↑ |

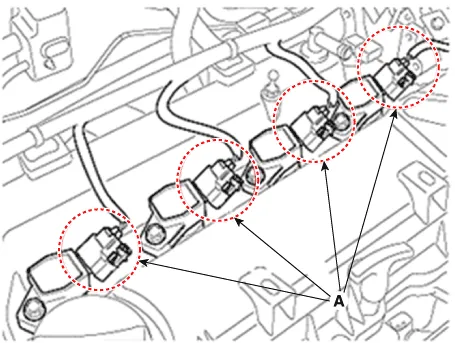

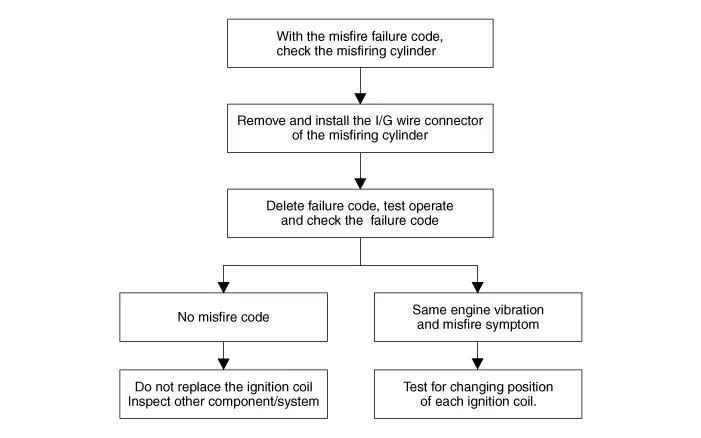

1.Remove the connector (A) and reinstall it.

• Do not move with spark plug at the same time (move the ignition coil only)

1.Turn ignition switch OFF and disconnect the battery negative (-) terminal.

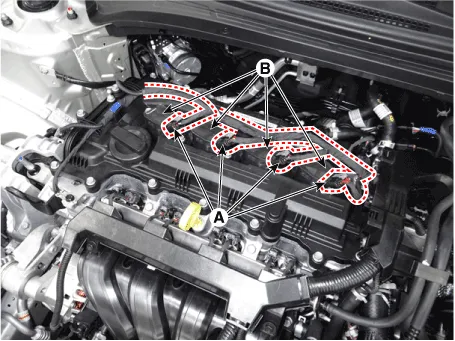

2.Remove the engine cover.

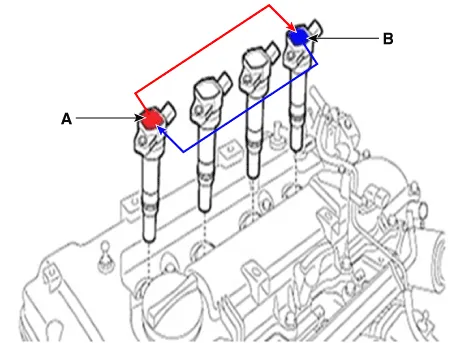

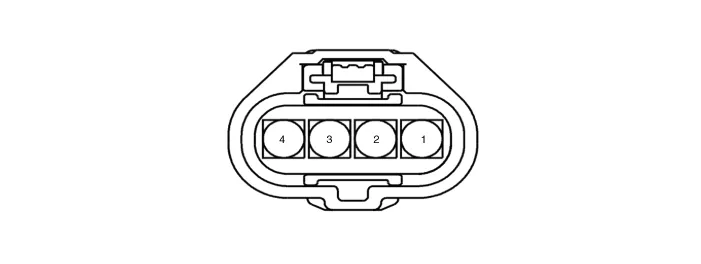

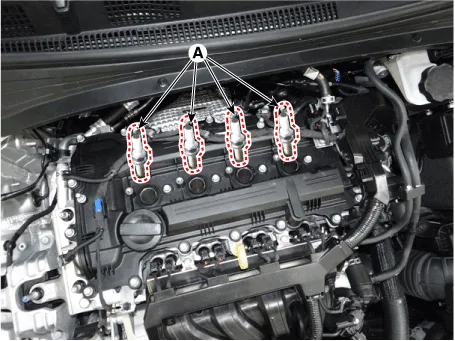

3.Disconnect the ignition coil connectors (A).

4.Remove the ignition coil after loosening the mounting bolts (B).

Ignition coil mounting bolt :9.8 - 11.8 N.m (1.0 - 1.2 kgf.m, 7.2 - 8.7 Ib-ft)

5.Install in the reverse order of removal.

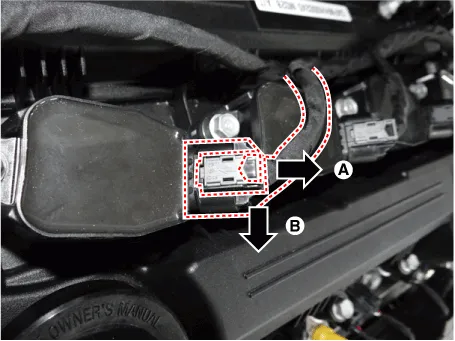

• When removing the ignition coil connector, pull the lock pin (A) and push the clip (B).

Spark Plug

| Item | Specification |

| Type | SILZKR7E9 |

| Gap | 0.8 - 0.9 mm |

| (0.0354 - 0.0394 in.) | |

| Electrode Material | Nickel Alloy |

1.Accelerate the engine to about 3,000 rpm 3 times or more.

2.Remove the spark plug.

3.Check the spark plug visually.If the electrode is dry, the spark plug is normal.If the electrode is wet, check the damage and electrode gap as below.

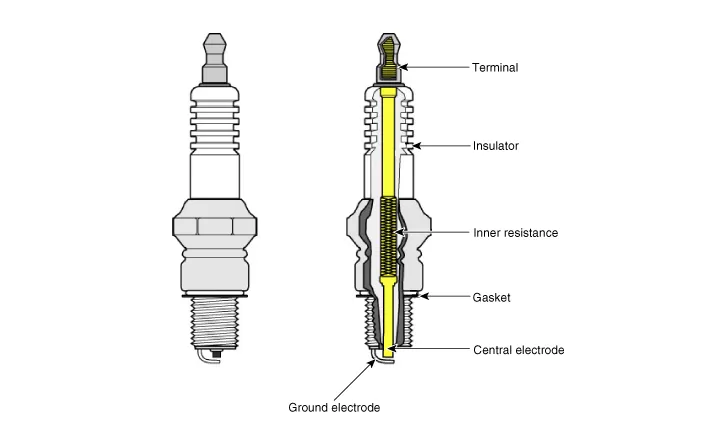

1.Check the spark plug for any damage on its thread and insulator.If there is damage, replace the spark plug.

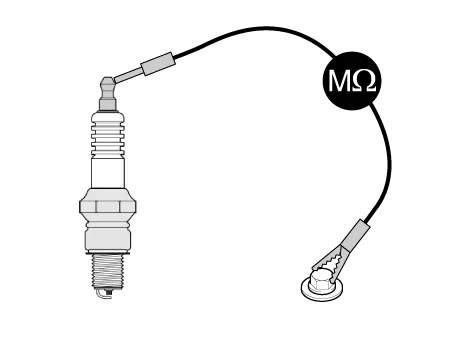

2.Check the electrode. Measure the insulation resistance with an ohmmeter.If the resistance is less than the specified value, adjust the electrode gap.

Specification : 10 MΩ or more

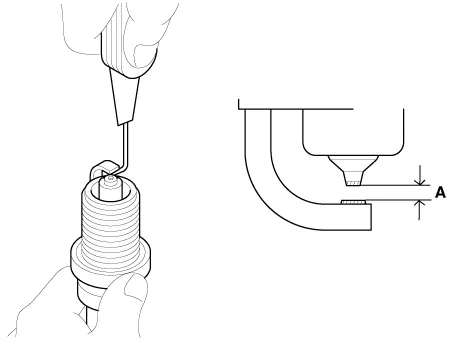

3.Check the spark plug electrode gap.If the gap is greater than the maximum, replace the spark plug.

Spark plug electrode gap : 0.8 - 0.9 mm

• If adjusting the gap of a new spark plug, bend only the base of the ground electrode. Do not touch the tip.Never attempt to adjust the gap on a used plug.

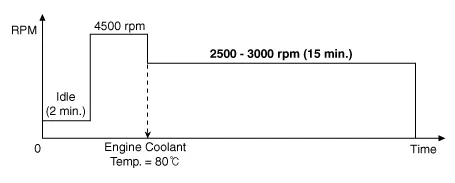

1.Start the engine and keep the engine running at idle for 2 minutes.

2.Step on the accelerator pedal and hold it steady at 4500 rpm with the shift lever in N position to warm up the engine until the temperature of the engine coolant reaches 80℃.

3.Keep the engine running at 2500 - 3000 rpm in the N position for 15 minutes.

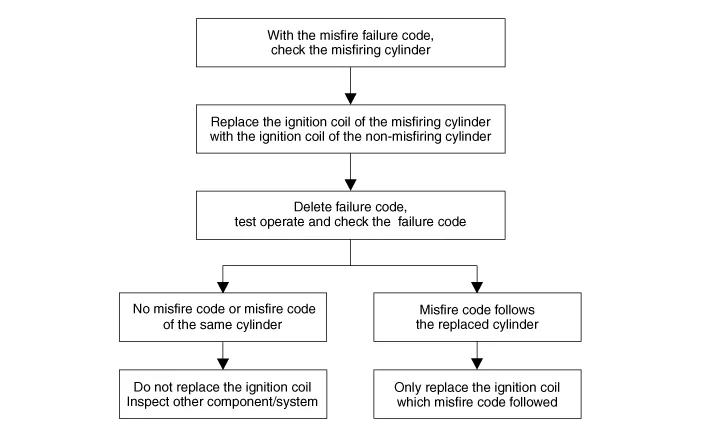

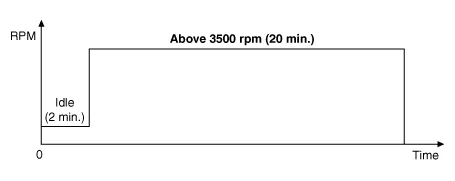

• The 2nd method should be performed only if the 1st method fails (the misfire-related codes recur).

1.Start the engine and keep the engine running at idle for 2 minutes.

2.Drive the vehicle for over 20 minutes, keeping the engine speed above 3500 rpm.

• If equipped with manual transaxle, shift the gear properly for keeping the engine speed above 3500 rpm.

1. Remove the ignition coil. (Refer to Ignition System - "Ignition Coil")

2.Using a spark plug wrench, remove the spark plug (A).

3.Install in the reverse order of removal.

Tightening torque : 14.7 - 24.5 N.m (1.5 - 2.5 kgf.m, 10.8 - 18.0 Ib-ft)

• Be careful that no contaminates enter into spark plug holes.

Other information:

Hyundai Accent (HC) (2017 - 2022) Service Manual: Tire Pressure Monitoring System (TPMS)

(1) Low Tire Pressure / TPMS Malfunction Indicator Lamp (2) Low Tire Pressure / Tire Pressure Monitor / TPMS Malfunction Display (shown on the cluster LCD display)Hyundai Accent (HC) (2017 - 2022) Service Manual: Installing a Child Restraint System (CRS)

WARNING Before installing your child restraint system always: Read and follow the instructions provided by the manufacturer of the child restraint. Read and follow the instructions regarding child restraint systems in this manual. Failure to follow all warnings and instructions could increase the risk of the SERIOUS INJURY or DEATH if an accident occurs.

Contents

Categories

- Manuals Home

- Hyundai Accent Owners Manual

- Hyundai Accent Service Manual

- Questions & Answers

- Video Guides

- Useful Resources

- New on site

- Most important about car

- Privacy Policy

0.0065