Hyundai Accent (HC): Driveshaft and axle

Hyundai Accent (HC) (2017 - 2022) Service Manual / Driveshaft and axle

Contents:

- Specifications

- Special Service Tools

- Troubleshooting

- Front Axle Assembly

- Driveshaft Assembly

- Rear Axle Assembly

Specifications

| Engine | Transaxle | Joint type | Max. permissible angle | ||

| Outer | Inner | Outer | Inner | ||

| GAMMA 1.6 | AT / MT | BJ#22 | TJi#22 | 46.5° | 23° |

| Item | N.m | kgf.m | lb-ft | |

| Front | Hub nuts | 107.9 - 127.5 | 11.0 - 13.0 | 79.6 - 94.0 |

| Driveshaft caulking nut | 274.6 - 294.2 | 28.0 - 30.0 | 202.5 - 217.0 | |

| Strut assembly to knuckle | 98.1 - 117.7 | 10.0 - 12.0 | 72.3 - 86.8 | |

| Front caliper to knuckle | 78.5 - 98.1 | 8.0 - 10.0 | 57.9 - 72.3 | |

| Wheel speed sensor mounting bolt | 7.8 - 11.8 | 0.8 - 1.2 | 5.8 - 8.7 | |

| Disc fixing screw | 4.9 - 5.9 | 0.5 - 0.6 | 3.6 - 4.3 | |

| Lower arm to knuckle | 58.8 - 70.6 | 6.0 - 7.2 | 43.4 - 52.1 | |

| Tie rod end castle nut | 24.5 - 34.3 | 2.5 - 3.5 | 18.1 - 25.3 | |

| Rear | Hub nuts | 107.9 - 127.5 | 11.0 - 13.0 | 79.6 - 94.0 |

| Rear caliper to torsion beam axle | 63.7 - 73.5 | 6.5 - 7.5 | 47.0 - 54.2 | |

| Wheel speed sensor cable mounting bolt | 8.8 - 13.7 | 0.9 - 1.4 | 6.5 - 10.1 | |

| Disc fixing screw | 4.9 - 5.9 | 0.5 - 0.6 | 3.6 - 4.3 | |

| Rear herb assembly to torsion beam axle | 49.0 - 58.8 | 5.0 - 6.0 | 36.2 - 43.4 | |

• Replace caulking nuts with new ones after removal.

| Engine | Joint type | Lubricants | Quantity |

| GAMMA 1.6 | Outer | RBA | 90g + 10g |

| Inner | CW-13TJ | 135 g + 10g |

Special Service Tools

| Tool(Number and Name) | Illustration | Use |

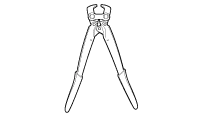

| 09495-3K000 Band installer |

| Installation of ear type boot band |

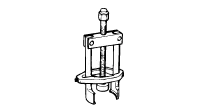

| 09568-1S100 Ball joint puller |

| Saperate the ball joint from the front axle |

| 09495-33000 Puller |

| Removal of spider assembly from a drive shaft |

Troubleshooting

| Trouble Symptom | Probable cause | Remedy |

| Vehicle pulls to one side | Scoring of driveshaft ball joint | Replace |

| Wear, rattle or scoring of wheel bearing | Replace | |

| Defective front suspension and steering | Adjustment or Replace | |

| Vibartion | Wear, damage or bending of driveshaft | Replace |

| Driveshaft rattle and hub serration | Replace | |

| Wear, rattle or scratching of wheel bearing | Replace | |

| Shimmy | Defective wheel balance | Adjustment or Replace |

| Defective front suspension and steering | Adjustment or Replace | |

| Excessive noise | Wear, damage or bending of driveshaft | Replace |

| Rattle of driveshaft and worn hub splines | Replace | |

| Wear, rattle or scoring of wheel bearing | Replace | |

| Loose hub nut | Adjustment or Replace | |

| Defective front suspension and steering | Adjustment or Replace |

Front Axle Assembly ➤

Driveshaft Assembly ➤

Rear Axle Assembly ➤

Other information:

Hyundai Accent (HC) (2017 - 2022) Service Manual: Head Restraints

The vehicle's front and rear seats have adjustable head restraints. The head restraints provide comfort for passengers, but more importantly they are designed to help protect passengers from whiplash and other neck and spinal injuries during an accident, especially in a rear impact collision. Correct head restraint height and distance are an important part of overall Hyundai Accent occupant safety.Hyundai Accent (HC) (2017 - 2022) Service Manual: Description and Operation

- Description of ESP Optimum driving safety now has a name : ESP, the Electronic Stability Program.ESP recognizes critical driving conditions, such as panic reactions in dangerous situations, and stabilizes the vehicle by wheel-individual braking and engine control intervention with no needfor actuating the brake or the gas pedal.ESP adds a further function known as Active Yaw Control (AYC) to the ABS, TCS, EBD and ESP functions.

Contents

- Specifications

- Special Service Tools

- Troubleshooting

- Front Axle Assembly

- Driveshaft Assembly

- Rear Axle Assembly

Categories

- Manuals Home

- Hyundai Accent Owners Manual

- Hyundai Accent Service Manual

- Questions & Answers

- Video Guides

- Useful Resources

- New on site

- Most important about car

- Privacy Policy

Copyright © 2026

0.0079

0.0079